180 ton water cooled screw industrial chiller

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Yantian, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 2000 set/month |

| Supply Ability: | 2000 set/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO99001,CE |

| HS Code: | 8418692090 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Yantian,Hongkong |

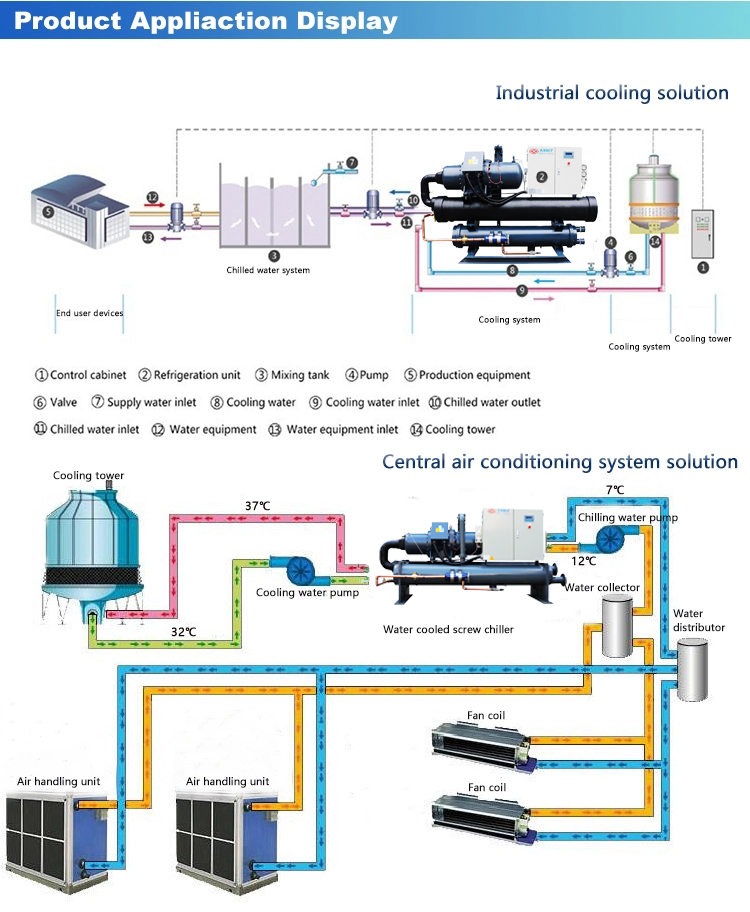

Screw type industrial water chiller, water cooled screw chiller trane, screw water cooled liquid chiller: The characteristics of the screw chiller are used in sheet materials, sunlight panels, wood-plastic doors, PVC doors, door lines, profile pipes, and water supply pipes. The heat temperature difference Δt can increase the heat transfer, and vice versa. Used for hot rolling, paper fabric, PVC sheet extrusion, plastic film, composite materials, conveyor belts, mirror rolls for bronzing machines. The unit is easy to install, easy to clean, flexible to move, all-metal paint frame, anti-rust and anti-vibration treatment, low noise, high efficiency heat exchange material, and high energy efficiency ratio.

50Hz/60Hz cold storage Screw Water Chiller industrial referigeration hospitals Water Cooled Screw Chiller In Chilling Equipment

1. Purpose

Water-cooled screw chillers are widely used in industrial environments, industrial plant cooling, chemical equipment, breeding, reaction kettles, fermentation tanks, hospitals, refrigeration and other industrial refrigeration projects of various sizes and industries. KDS screw chillers are our company ’s Years of experience in designing and producing water chillers, combined with the latest technological development and dedicated research, design and development of water chillers. This product keeps pace with the development trend of the times, adhering to the design concept of "high efficiency, reliability, energy saving and environmental protection", and providing users with an excellent freezing equipment.

2. Features

The water-cooled screw chiller adopts internationally renowned brand screw compressors, and is equipped with high-quality and high-efficiency copper tubes to make condensers, evaporators and world-famous brand control elements. , Its beautiful and exquisite shape design and reliable and stable high-performance quality are outstanding among similar products!

Compressor features:

² The compressor uses an international brand, a new type of high-efficiency screw rotor compressor, which is 20% -30% higher than the general compressor, and has obtained European and American patents and ISO9001 international quality certification.

² High efficiency control 5: 6 patented asymmetric rotor tooth profile.

² Capacity control can adopt four-stage (100% -75% -50% -25%) or three-stage (100-66% -33%) and stepless control systems.

² High-efficiency silicon steel and special groove design, and equipped with internal and external omnidirectional design cooling flow channels, so that the compressor motor can exert the highest efficiency under any load.

² Unique built-in oil pressure system, no oil pump is needed to ensure that the compressor maintains the best lubrication effect.

² The oil separator adopts double-layer filtering method, which has good oil filtering effect, and the heat exchanger can exert its maximum capacity.

² High efficiency, low noise and low vibration.

² The system is equipped with functions such as motor overload, short circuit protection, overheating, high pressure, low pressure, compressor delayed start protection, water flow protection, etc. The unit operates safely and reliably.

3. Working principle

The main components of the unit are: compressor, condenser, filter drier, gas-liquid separator, expansion valve, evaporator, and control instruments and control elements.

Related Keywords