Wear-resistant and oil-resistant TPR for Oil Gas Resistant TPR Protector

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Wear-resistant and oil-resistant TPR for Oil Gas Resistant TPR Protector

Product Description

| Commodity | TPR | Quality inspection date | 2018/12/13 | |||

| No. | Item | Unit | Standard | Determine scope | Testing result | Test method |

| 1 | Appearance | Visual test | Natural color | Natural color | ||

| 2 | Hardness | Shore A | ASTM-D2240 | 0~100 | 30C | indoor temperature℃ |

| 3 | Density | SP.Gr | ASTM-792 | 1.15±0.05 | 1.2 | |

| 4 | Solution flow index | g/10min | ASTM-D1238 | 5~20 | 13 | 190℃,2.16kg |

| 5 | Tensile strength | Mpa | ASTM-D412 | ≥5 | 7.8 | indoor temperature 500mm/min |

| 6 | Elongation | % | ASTM-D412 | ≥500 | 550 | |

| 7 | Tear strength | KN/m | ASTM-D624 | ≥20 | 23 | |

| Manufacturing technique | ||||||

| Barrel temperature | Range ℃ | Typical value ℃ | ||||

| Forepart | 150-190 | 170 | ||||

| Midpiece | 150-210 | 180 | ||||

| Back end | 150-210 | 180 | ||||

| Orifice/Die-head | 160-200 | 180 | ||||

| Upper limit of processing temperature ℃ | 220 | |||||

| Time of drying | Generally there is no need to dry,If the storage environment is humid or the production of products surface requirements higher parts,dry in a hot air oven for 2 to 4 hours | |||||

| 1.The above data is only for reference. The above data can be adjusted according to different models,molds and product requirements.2.Do not allow the material in the barrel to stay too long too long,Please use PE to clean the machine before stopping it. | ||||||

| Materials can be developed and produced according to clients' requirements | ||||||

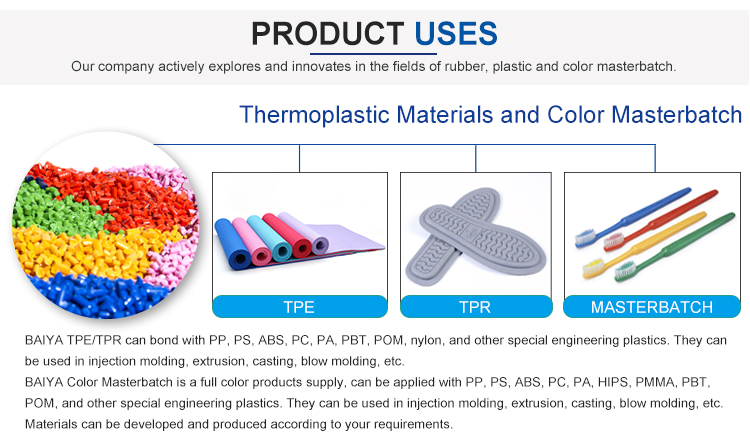

Product uses

Company Information

Product Case

Packaging & Shipping

FAQ

Contact us

Related Keywords

Related Keywords

You May Also Like

You May Also Like