PSA Oxygen Generator Aluminum Extrusion Barrel

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Others |

|---|---|

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean |

Psa Oxygen Generation Plant for Hospital

Features:

● Fast start-up, qualified oxygen can be provided within 15-30 minutes;

● The equipment is fully automatic, and the whole process can be unattended;

● Efficient molecular sieve packing, tighter, more solid, and longer service life;

● The pressure, purity, and flow are stable and adjustable to meet the different needs of customers;

● Reasonable structure, safety and stability, low energy consumption;

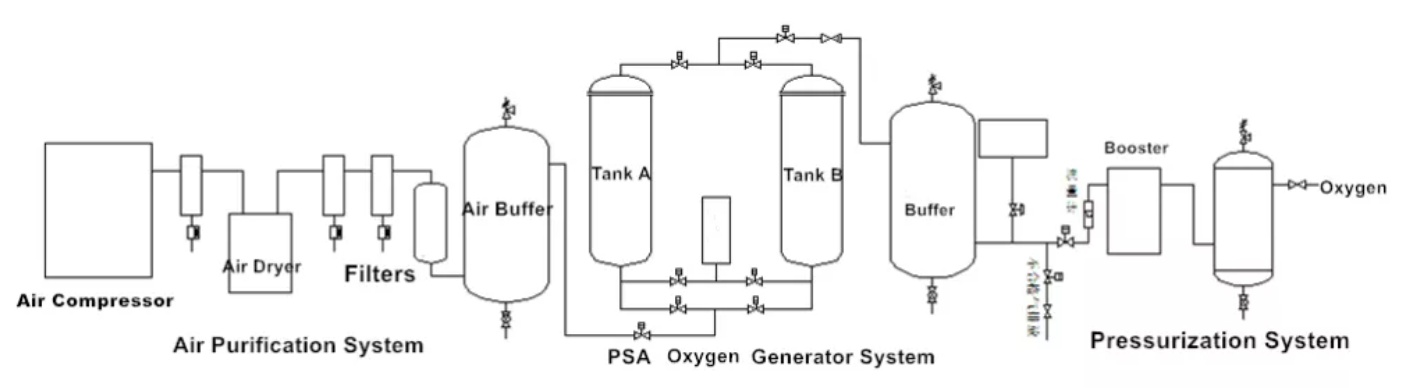

Principle:

This process uses molecular sieves with capillary pores as adsorbents, and utilizes the difference in diffusion rate of oxygen molecule O2 and nitrogen molecule N2 in molecular sieve. Nitrogen and CO2 molecules in the air are absorbed into the pores, while most of the oxygen molecules O2 flow through the capillary pores into the oxygen collecting and storing tank in the later stage to be enriched. Molecular sieve has the characteristics of adding air pressure adsorption capacity increasing, and reducing air pressure adsorption capacity reducing, using this characteristic, the pressure swing adsorption method can be used to carry out continuous and uninterrupted oxygen and nitrogen separation. So as to achieve the preparation of 35%-95% purity room temperature oxygen. The PSA oxygen generator adopts a dual-tower parallel design. When tower A reaches saturation, it will switch to tower B for oxygen production through pressure equalization and other processes. At this time, tower A is vented and purged and regenerated, waiting for the next cycle of the oxygen generator; thus, double-tower alternate oxygen production is realized. In the latter stage of the oxygen collection process tank, high-purity continuous supply of oxygen is obtained, and finally the pressure is stabilized by adjusting the pressure and then transported to the gas point through the pipeline.

Technical indicators

Oxygen production: 5 ~ 1000Nm3/h

Purity of oxygen: 93%±2%

Oxygen pressure: ≤3 bar(Adjustable)

Dew point: ≤-40ºC(Adjustable)

|

Model |

O2 Cpacity(Nm3/h) |

Purity |

|

|

||

|

HO2020 |

20 |

93%±2% |

|

HO2040 |

40 |

93%±2% |

|

HO2050 |

50 |

93%±2% |

|

HO2080 |

80 |

93%±2% |

|

HO2100 |

100 |

93%±2% |

|

HO2150 |

150 |

93%±2% |

|

HO2200 |

200 |

93%±2% |

Technical characteristics

⊙ The equipment has the advantages of low energy consumption, low cost, strong adaptability, fast gas production and easy adjustment of purity.

⊙ Perfect process design and best use effect;

⊙ Modular design is designed to save land area.

⊙ The operation is simple, the performance is stable, the automation level is high, and it can be realized without operation.

⊙ Reasonable internal components, uniform air distribution, and reduce the high speed impact of airflow;

⊙ Special carbon molecular sieve protection measures to extend the life of carbon molecular sieve.

⊙ The key components of famous brands are the effective guarantee of equipment quality.

⊙ The automatic emptying device of national patent technology guarantees the nitrogen quality of finished products.

⊙ It has many functions of fault diagnosis, alarm and automatic processing.

⊙ Optional touch screen display, dew point detection, energy saving control, DCS communication and so on.

Company Overview

KunPeng is located in Shenzhen, China. We specialized in the the design and manufacture of cryogenic air separation units, VPSA oxygen generators, compressed air purification equipment, PSA nitrogen generators, PSA oxygen generators, oil-free gas boosters, electric and pneumatic intelligent control valves, Temperature Control valves, Shut-off valve manufacturers, SMT cleaning equipment, etc.

The main products of ROC: SMT Cleaning Machine, PSA oxygen / nitrogen generator, wafer cleaning equipment, PCBA Cleaning Machine, PCB Separator, SMT Spare Parts, Reflow / Wave Soldering Machine, SMT Nozzle, SMT Feeder etc. If there is any need, please contact us.

The product structure is matched up and down,one-stop service. The modern standard workshops and advanced product testing devices. The company always adheres to the business philosophy of"integrity, cooperation, and win-win", takes the development path of technology, diversification,scale, and develops toward high-tech industrialization. The company's products use "KP" as the registered trademark and are widely used in metallurgy and coal, power electronics, petrochemical, bio medicine, tire rubber, textile and chemical fiber, food preservation and other industries.

Related Keywords