High Purity Gas Nitrogen Production Machine

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

High Purity Gas Nitrogen Production Machine

This High Purity Gas Nitrogen Production Machine consists of a high efficiency degreaser, a refrigerated dryer, a precision filter and an activated carbon filter.

After the air passes through the air compressor, it first enters the air buffer tank for buffering, and then enters the high-efficiency oil remover to remove most of the oil, water, dust and other impurities. Then it is further removed by the refrigerated dryer to remove water and dust, and finally enter the activated carbon filter to further remove oil.

The activated carbon filter specially designed by our company can be used to prevent possible trace oil penetration, to ensure that the carbon molecular sieve is effectively protected, and the service life of the machine is prolonged.

At present, nitrogen generation devices are widely used in safety protection gas, replacement gas, nitrogen injection, tertiary oil recovery, coal mine fire and fire extinguishing, nitrogen-based atmosphere heat treatment, anti-corrosion and explosion-proof, electronics industry, integrated circuits, etc.

The main products of ROC: SMT Cleaning Machine, PSA oxygen / nitrogen generator, wafer cleaning equipment, PCBA Cleaning Machine, PCB Separator, SMT Spare Parts, Reflow / Wave Soldering Machine, SMT Nozzle, SMT Feeder etc. If there is any need, please contact us.

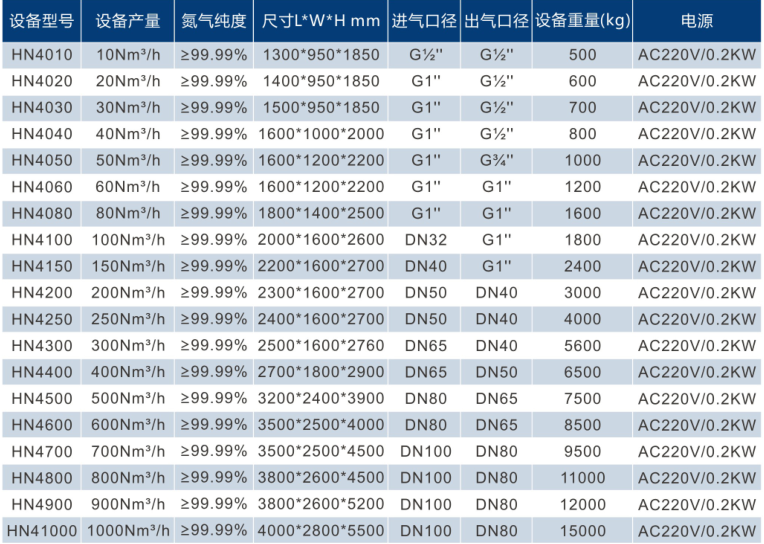

Technical indicators

Nitrogen capacity: 1- 2000Nm3/h

Nitrogen purity: 95%-99.999%

Nitrogen pressure: 0.5-0.8Mpa( boost for high pressure

Nitrogen dew point: s-40.C(Atmosphere pressure)

Customized pressure, purity and capacity ranges.

Technical characteristics

1.The material source is from the nature, the system only needs compressed air and power, so the cost of power and operation is less

2. Nitrogen purity is easy to adjust, it is only affected by the capacity, purity of normal nitrogen is at the range of 95%-99.99%(can be adjusted), purity of high nitrogen is at the range of 99%-99.999%(can be adjusted)

3. The system is automatic, quick starting and no need to monitor. One button for start and stop, run 10-15 minutes to generate the N2 air

4. The working progress is easy, the configuration is compact, the landing space is less and the environment is well-adapted

5. Snow storm filling can avoid the damage of CMs

6. Digital flow meter has pressure compensation, it is highly precise meter which can monitor the progress, it can test quick flow and accumulate the total capacity

Send Inquiry Please bring the following description, we have more models to recommend to you ~! Thank you~!

| Technical Information | Your Kind Requirement |

| Capacity |

_________Nm³/h |

| Purity | _________% |

| Outlet Pressure | _________Mpa or Bar |

| Power |

________V/HZ |

Related Keywords