Plastic Precision Car Parts

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Supply Ability: | 1 set |

| Payment Type: | T/T |

HanKing Mould Enginering Ltd. started the business in the year of 1996 as a china plastic injection mold maker in the line of mold making and injection molding in Longgang, Shenzhen, China. With continuous developments and progresses, we have become a professional Chinese plastic injection tooling company, offering custom plastic injection molding service, plastic molding manufacturing and other mould making services.

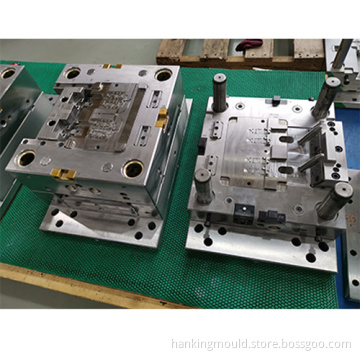

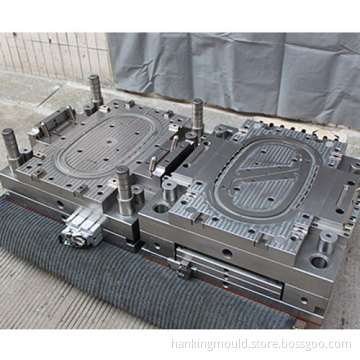

Name:Plastic Precision Car Parts

Mould Type: Plastic Car Parts Mould

Production Material: PC, PP, PA6, PA66, PE, ABS, HDPE, TPE, TPU, PET, PPS, POM, PBT, PMMA, PPS, SAN, etc.

No of Cavities: Single or Multi cavity

Core Material: 2344, S136,H13,S7, NAK80,SS420, P20 and other steel according to customer mould requirement.

Cavity Material: 2344, S136,H13,S7, NAK80,SS420, P20 and other steel according to customer mould requirement.

Mold base: LKM, HASCO, DME equivalent and customized.

Injection System: cold runner, hot runner

Type of gating: Side gate, Sub gate, Pin point gate, Edge gate etc

Surface finish: VDI EDM, Texture, SPI standard, etc

Hot runner: Mold Masters, Yudo, Synventive, Incoe, etc.

Lead time: 6 weeks

Shot life: 1,000,000

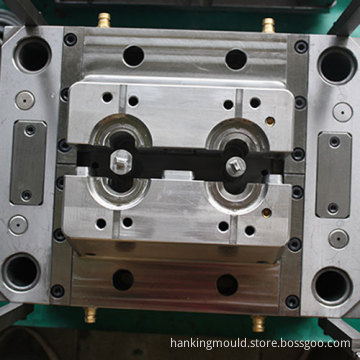

Mold making procedure, the first step is mould drawing design, the 2D & 3D mould design should be confirmed by customer.

Customer sends the plastic parts drawing. HanKing design tooling drawing according to part drawing. We send 2D mould design to customer for confirmation and start 3D mould design after 2D is approved.

After mould design is confirmed, we will order materials, steel, components, mould core and cavity steel, mould base, normally it will take 1weekto 3 weeks depends on the structure of the mould. All mold making procedures are taking place in house.