Insulation G10 Epoxy Glass Fiberglass Laminate Sheet

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

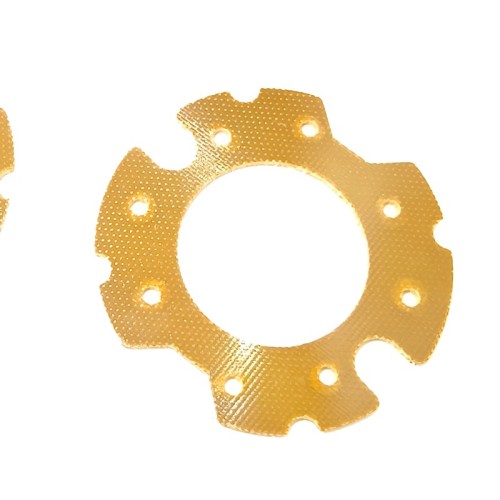

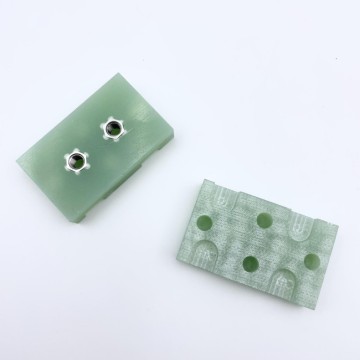

Insulating plate processing parts are made of mica orfiberglass plate as base material.They can be processed

byrolling,punching,turning,dilling,

grinding,miling,model pressing and othermeans are adopted.According to customerrequirements,it can beprocessed into various sies ofinsulating gasket, insulating round gasket and insulating flange,etc.

It is suitable for high temperature insulation of various electrical appliances and electric heating elements.

Glass Fiberboard Differences and Buying Guide

Main Differences

Color

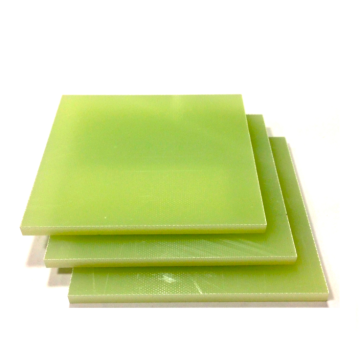

- FR-4: aqua green

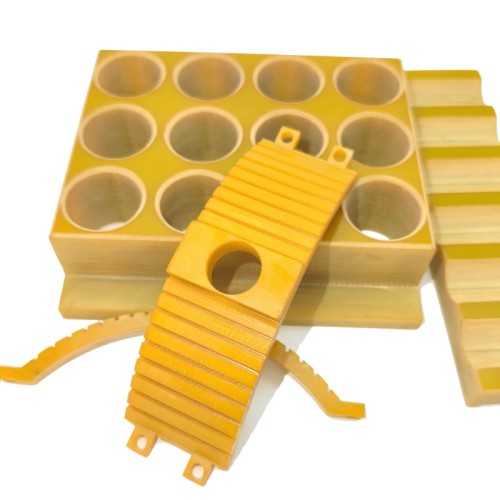

- 3240: yellow color

- Ordinary fiberglass board: white, light yellow, green, etc.

Main components

- FR-4 glass fiber board (water green): glass fiber + epoxy resin

- 3240 Epoxy board (yellow): paper/cloth base + phenolic/epoxy resin

- Ordinary Fiberglass Sheet: Glass Fiber + Resin

Temperature resistance

- FR-4: 150°C-180°C+, more heat resistant

- 3240: 130°C-155°C

- Ordinary fiberglass boards: depending on the type of resin, some have lower temperature resistance.

Insulation properties

- FR-4: excellent, suitable for high-frequency circuits

- 3240: good, suitable for general electrical equipment

- General fiberglass: insulation depends on resin type

Strength and hardness

- FR-4: high density, high strength, not easily deformed

- 3240: Higher strength, but slightly lower than FR-4.

- Ordinary fiberglass board: average mechanical strength, suitable for light structures

Areas of application

- FR-4: High-end PCB circuit boards, electronic equipment, motor insulation

- 3240: mechanical equipment, electrical insulation boards, gaskets

- Ordinary fiberglass boards: general industry, low load mechanical structures

Corrosion resistance

- FR-4: acid and alkali resistance, moisture resistance, chemical corrosion resistance

- 3240: general corrosion resistance

- Ordinary fiberglass board: depending on the type of resin

Processing performance

- FR-4: Suitable for CNC precision machining

- 3240: Easy to cut, punch, good processability

- Ordinary fiberglass board: suitable for general processing

Suggestions for selection

If used for high-end electronic equipment, circuit boards, electrical equipment, choose FR-4 glass fiber board.

If used for general electrical insulation, mechanical gaskets, 3240 epoxy board is more cost-effective.

If used for general mechanical structure, does not involve high temperature and high pressure environment, fiberglass board can meet the demand.

Summarize

FR-4 (green) → High-end insulation, high-temperature corrosion resistance, suitable for circuit boards and electrical equipment.

3240 (yellow) → cost-effective, commonly used for insulation of mechanical equipment and electricians.

Ordinary fiberglass board → general industrial use, strength and insulation properties of ordinary

Related Keywords

Related Keywords