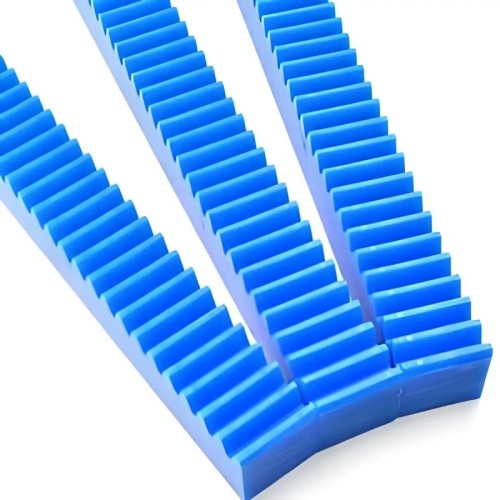

CNC Nylon MC901 Plastic Bevel Gear

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

MC nylon wear-resistant, corrosion-resistant, self-lubricating

MC nylon products have become the star among engineering plastics with its excellent performance and wide range of applications. It is not only light in weight and high in strength, but also possesses a variety of properties such as self-lubricating, wear-resistant, corrosion-resistant and insulating, which are used in almost all industrial fields. The following are some of the main types of MC nylon:

MC Nylon (Ivory): This unmodified cast nylon 6 is very close to the properties of nylon 66, with excellent overall performance, high strength, stiffness and hardness, creep resistance, abrasion resistance, heat aging resistance, and good machinability.

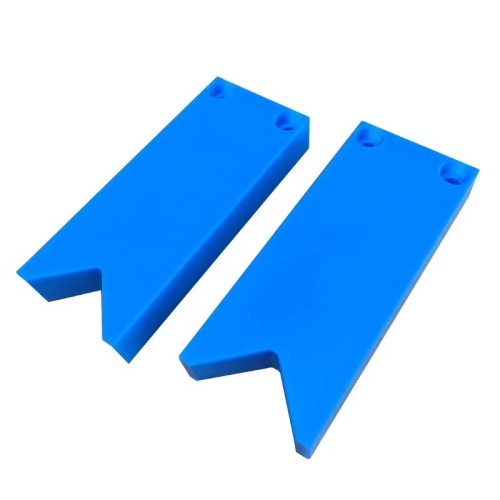

MC901 (blue): This modified nylon 6 is blue in color, high toughness, good flexibility, fatigue resistance, is the ideal material for gears, racks and transmission gears.

PA6+Oil (green): This cast nylon 6 has self-lubricating properties and is designed for parts that cannot be lubricated, have high loads, and run at low speeds, with a low coefficient of friction and improved wear resistance.

PA6+Molybdenum disulfide (gray-black): This nylon containing molybdenum disulfide powder improves load carrying capacity and wear resistance without sacrificing the impact and fatigue resistance of unmodified cast nylon, and is widely used in the manufacture of gears, bearings, star wheels, and bushings.

PA6 + solid lubricant (gray): This cast nylon 6 contains a solid lubricant, which provides self-lubrication, excellent friction, outstanding wear resistance, and pressure-speed capability (5 times higher than ordinary cast nylon), and is particularly suitable for high-speed operation and moving parts that cannot be lubricated.

The versatility of MC nylon products allows them to excel in a variety of application scenarios, providing more choices for industry.

MC901 nylon English name: Monomer casting nylon, Chinese name: monomer casting nylon, is a widely used engineering plastics, almost all over the industrial field.

The molecular weight of MC nylon is as high as 7-10 million, which is 3 times of the general nylon 6 and nylon 66, thus its comprehensive mechanical properties are much better than other nylon materials.

Characteristics: good overall performance, high strength, stiffness and hardness, creep resistance, abrasion resistance, heat aging resistance (applicable temperature range -40 degrees ----120 degrees), good machinability.

Uses: cast nylon is widely used in place of wear-resistant parts of machinery and equipment, replacing copper and alloys as wear-resistant wear parts of equipment. Such as bushings, shaft tiles, bushings, liners, gears, worm gear roller copper guide, piston rings, seals, sliders, ball bowls, impellers, blades, cams, nuts, valves, pipelines, stuffing boxes, racks, pulleys, pump rotors, and so on. Due to the simple structure of process and mold, the manufacturing cost is relatively low, and become an ideal material to replace copper, stainless steel, aluminum alloy, PTFE and so on.

Related Keywords

Related Keywords