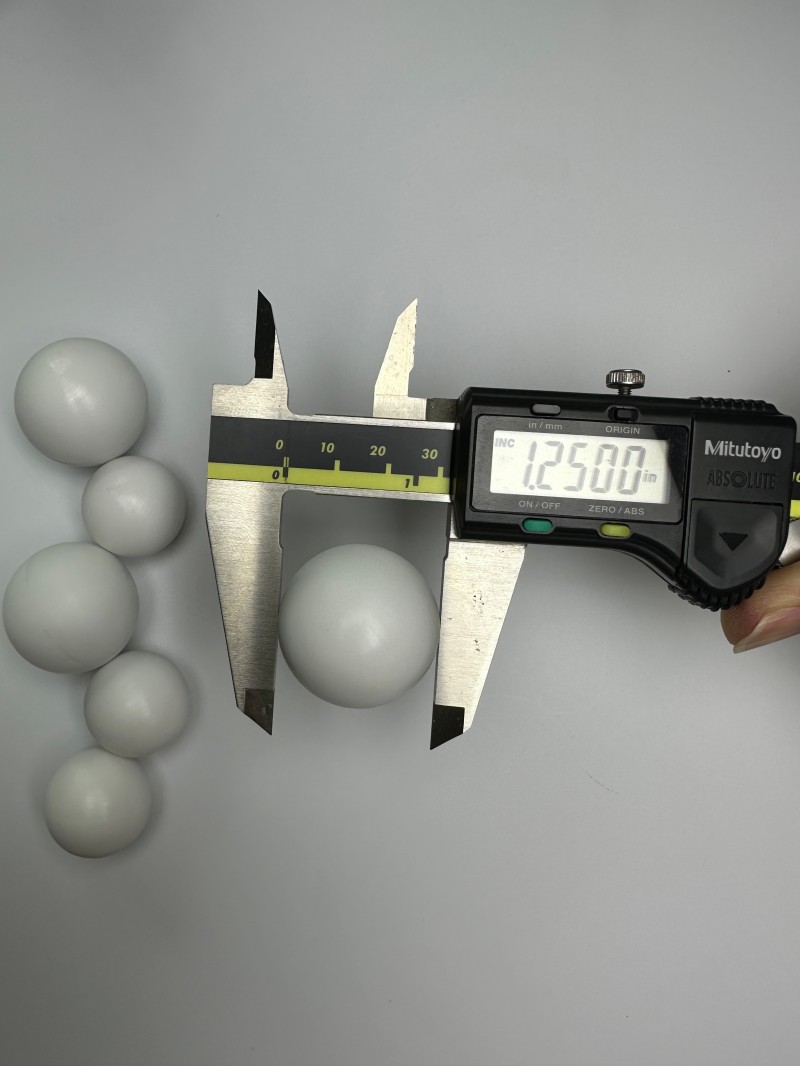

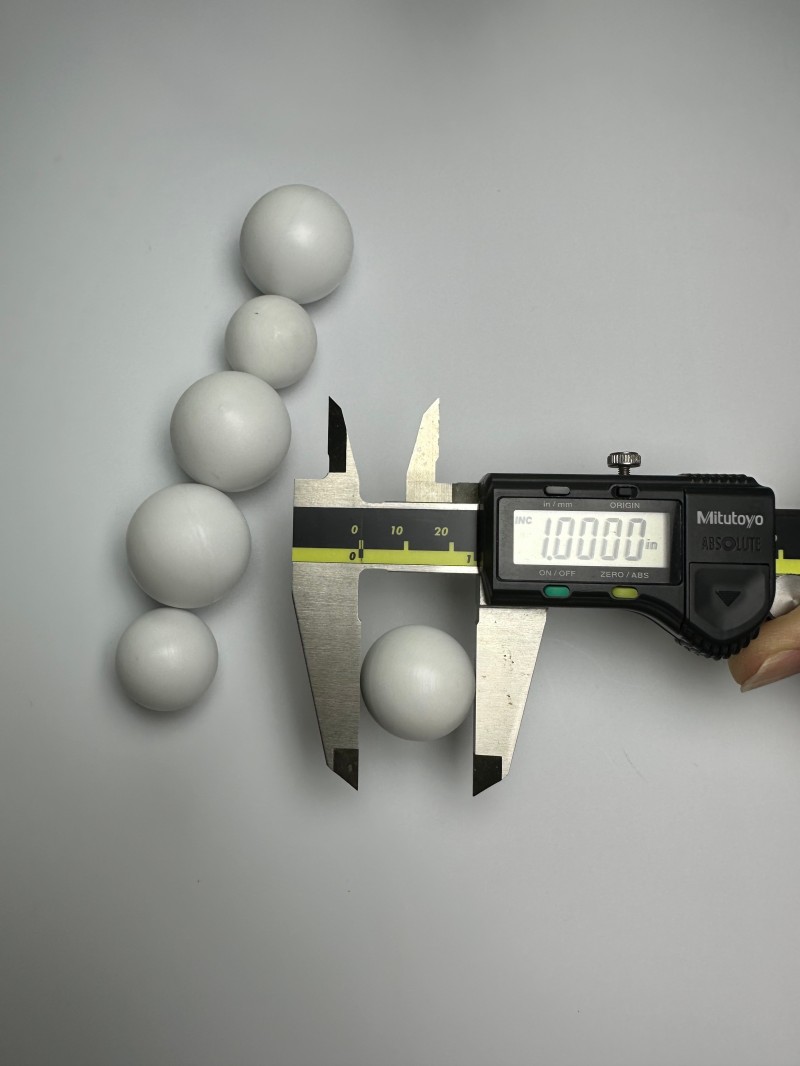

Ertalyte™ PET-P Polyethylene Terephthalate solid ball

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Land, Ocean, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Transportation: | Land,Ocean,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

Polyethylene terephthalate product line (Ertalyte® PET-P)

Good mechanical strength, stiffness and hardness

Good creep resistance

Low and stable coefficient of friction

Good abrasion resistance (no less than or even better than nylon materials)

good dimensional stability (better than paraformaldehyde)

Good anti-staining ability

Better acid corrosion resistance than nylon or paraformaldehyde

Good electrical insulation properties

Physiologically inert (suitable for food contact)

Good resistance to high energy radiation (gamma- and X-rays).

Ertalyte® PET-P

Ertalyte® is a polyethylene terephthalate machined profile, Ertalyte® PET-P is a pure grade and Ertalyte® TX is a bearing grade.

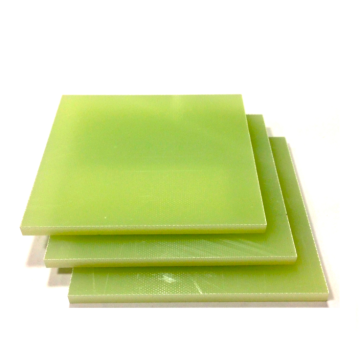

Ertalyte (colors: natural/white, black) are unreinforced, semi-crystallized, pure thermoplastic polyester (PET-P) profiles, which are particularly suitable for the manufacture of highly loaded and wear-resistant precision machine parts.

Ertalyte Natural (rods, sheets) are “food-grade” engineering plastic profiles.

Ertalyte is available in white and black, both of which comply with FDA food standards. Ertalyte White also meets USDA, 3A-Dairy and Canada AG standards. Ertalyte is an excellent material for food processing and industrial equipment components.

Applications

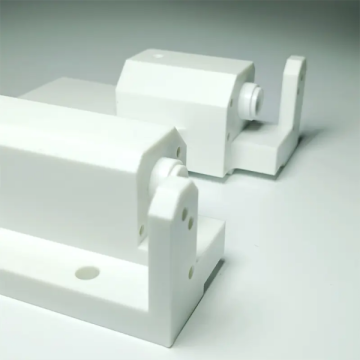

Manifolds

Process and test equipment manifolds machined from Ertalyte exhibit very good dimensional stability, excellent stain resistance and chemical resistance. (Previous materials: aluminum, paraformaldehyde)

Food Equipment Components

Many components in food production and processing equipment are machined from Ertalyte® - e.g. this burger forming mold. It meets tight tolerances and can be easily cleaned on site with cleaning chemicals. (Previous material: aluminum)

Conveyor belts, filter traces, positioning disks and rings

Stiffness and a hygienically clean appearance - combined with dimensional stability and resistance to dilute hydrochloric acid corrosion - make Ertalyte the ideal material for a wide range of medical test equipment components. (Previous materials: nylon, UHMWPE)

Ertalyte® TX

Ertalyte TX (color: light gray) is a specially formulated, modified polyester machined profile with uniformly dispersed solid lubricants, and is a superior bearing grade engineering plastic with self-lubricating properties.Ertalyte TX exhibits outstanding wear resistance, a lower coefficient of friction than Ertalyte, and higher pressure speed capabilities.

Ertalyte TX performs well at high pressures and high speeds, and is an excellent plastic for engagement with soft metals.

Ertalyte TX is available in a variety of sizes (sheet, rod, tube, etc.) and is Quadrant's “food grade” engineering plastic profile that meets FDA, USDA and 3A-Dairy food standards.

Applications

Dispensing Valves

Ertalyte® TX excels at high pressures and speeds, and is also a good choice for applications where soft metals engage with plastics. The dispensing valve for this food packaging machine is made of Ketron® PEEK-1000 and Ertalyte TX instead of stainless steel. Stainless steel components can cause excessive housing wear and unacceptable maintenance costs. The gap between the dispensing valve and the housing must be tight enough to avoid leakage.

Ertalyte® Product Family

Ertalyte® is an unreinforced semi-crystalline thermoplastic polyester based on polyethylene terephthalate (PET-P). The product range offers good dimensional stability, good abrasion resistance, low CoF, high strength and resistance to medium acidic solutions.

Ertalyte® TX Food Grade PET-P

Polyethylene Terephthalate

Material Properties

Excellent dimensional stability

Low water absorption for consistent mechanical and electrical properties

Good abrasion resistance, low CoF

High strength and stiffness

Good resistance to contamination

Ideal for high pressure and high speed conditions

Ertalyte® PET FG

Polyethylene Terephthalate

Material properties

Good abrasion resistance, low CoF

Meets the requirements of FDA 21 CFR § 177.1630 and EU 10/2011 food standards

High strength

Resistant to medium acidic solutions

High load-bearing capacity

Retains strength up to 180° F / 85° C

Ertalyte® SLP PET-P

Polyethylene Terephthalate

Material Properties

Good abrasion resistance, low CoF

High mechanical strength, high load capacity

Higher stiffness and better thermal properties compared to nylon or acetal

Customized for wind turbine yaw systems

Ertalyte® TX PET-P

Polyethylene Terephthalate

Material properties

High mechanical strength, stiffness and rigidity

excellent creep resistance

Low and constant CoF

Good abrasion resistance (comparable or better than nylon grades)

Excellent dimensional stability (better than polyacetal)

Physiologically inert (suitable for food contact)

Ertalyte® PET-P

Polyester

Material properties

Good abrasion resistance, low CoF

High strength

Resistant to medium acidic solutions

High load-bearing capacity

Retains strength up to 180° F / 85° C

Ertalyte® Sterra™ PET

Recycled Polyethylene Terephthalate

Material Properties

Good abrasion resistance

Low CoF

High strength

Resistant to medium acidic solutions

Maintains high loads

Better strength retention than nylon or acetal at 180°F (85°C)

Related Keywords

Related Keywords