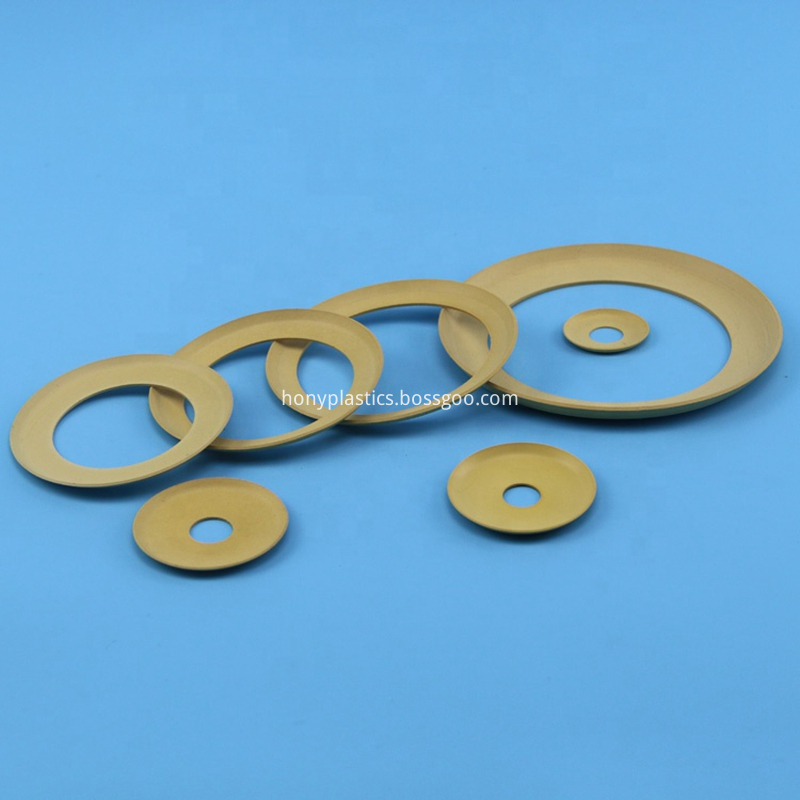

PTFE filled polyimide plastic spacer

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | Enough |

|---|---|

| Supply Ability: | Enought |

| Payment Type: | T/T,Paypal,Others |

| Incoterm: | FOB,CIF,EXW,DDU |

| Certificate: | ISO SGS REACH ROHS |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONYFLUO®Polyimide (PI) compound PTFE packing V rings / seals,Custom polyimide filled PTFE products wear resistance PI filled PTFE piston cup products,Polyimide is one of the organic polymer materials with the best comprehensive performance. It has the characteristics of high insulation, fatigue resistance, high temperature resistance, wear resistance, impact resistance, low noise and long service life. The mixed material formed by adding PI into PTFE has the characteristics of high and low temperature resistance, self lubrication, low noise and stable size. The material is mainly used for piston ring, oil-free cup, bearing sleeve, bearing bush, sealing washer and other parts.

Why is PTFE gasket the "originator" of the gasket industry?

The reason why PTFE gaskets are more special, from PTFE this material's strong performance, it is made of tetrafluoroethylene as a monomer polymerization of polymers, heat and cold resistance performance is superior, in -180 ℃ -260 ℃ temperature environment are able to use for a long time, but also acid and alkali resistance to corrosion, but also resistant to a variety of organic solvents, almost not dissolved in all the solvents. In addition to excellent high temperature resistance, PTFE material has a very low coefficient of friction and good lubricity.

With many advantages of PTFE material made of PTFE gasket also has many advantages.

Such as for a variety of temperatures in the environment of the working conditions, in the temperature range of -180 ℃ -250 ℃ can be used normally will not affect the performance;

Even in the -196 ℃ of the ultra-low temperature environment, but also has a good mechanical toughness, to maintain the elongation of 5%;

PTFE gaskets also have the best aging life of plastic gaskets, the use of a long cycle;

It has a low coefficient of friction and good self-lubrication;

Surface tension is also the smallest among all kinds of materials, will not adhere to any substance;

Good resilience, can be in high temperature, low temperature, high vacuum, shock vibration and other cyclic alternation and a variety of harsh conditions, to maintain superior sealing performance.

Where are PTFE gaskets used?

The use of PTFE gaskets and its characteristics are closely related, mostly used for temperature, pressure alternation drastic sealing parts of the connection, such as pipelines, valves, heat exchangers, pumps, and other flange connection sealing elements; in the petroleum, chemical, pharmaceutical, electric power and electrical power, iron and steel, machinery, metallurgy, shipbuilding, atomic energy, aerospace, instrumentation, calculators and other industries are widely used. Especially in the chemical and pharmaceutical industries, its acid and alkali resistance, high temperature resistance, resistance to a variety of organic solvents play a great role.

Main product

Related Keywords