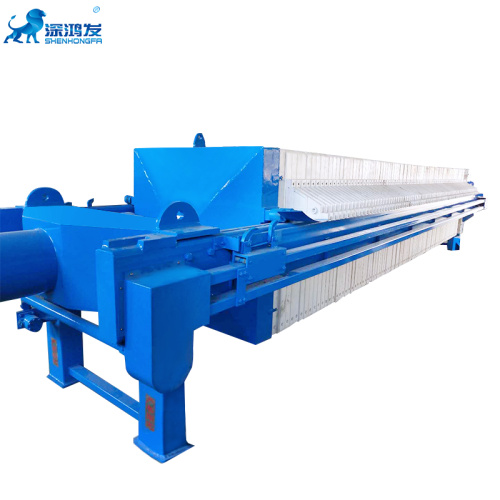

Sand Washing Mud Dewatering Equipment Filter Press

-

$3000.00≥1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Transportation:

- Ocean, Air, Express

- Port:

- SHENZHEN, TIANJIN, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 100set/month |

| Supply Ability: | 100sets/month |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Air,Express |

| Port: | SHENZHEN,TIANJIN,SHANGHAI |

Fully Automatic Chamber Filter Press with CE Certificate

After the sand washing sludge and sand sewage are filtered and separated by the van filter press in the sand washing field, the mud becomes two parts: dry mud cake and clean water, and the clean water can be used for sand washing again. The mud produced is filtered by the plate frame van filter press again, and the cycle repeats. This is the work of the van filter press in the sand washing field, and the cycle continues. It can maximize the benefits of the sand field, and the filtrate after filtration is very clear, and it can be recycled completely. How is the disposal effect of the side filter press in the sand washing field?

1. If the side filter press is found to have oil leakage or abnormal shaking, loud noise or abnormal action in the work, the equipment should be stopped in time for inspection and analysis of the reasons;

2. In the process of analysis, equipment failure should be ruled out first, and then see if it is caused by external factors. When the problem is not found, it is not possible to open the operation of filtering again;

3. If there is abnormal noise in the filtering process of the van-type filter press, it should also stop working and start checking. The situation should be reported to the maintenance personnel, and the maintenance personnel should check and repair the problem.

4. In the inspection process of the van filter press, it is not possible to adjust the parts at will when the problem is not found, so as not to cause the fault after starting.

5, the side filter press can not work under pressure;

6, the relief valve can not be adjusted at will;

7. Before the van filter press starts to run, it is found that the number of plate and frame is not enough, or that the shift is greater than the piston stroke, it can not be started to use.

8, the operator can not leave the post without authorization when using the plate frame type filter press.

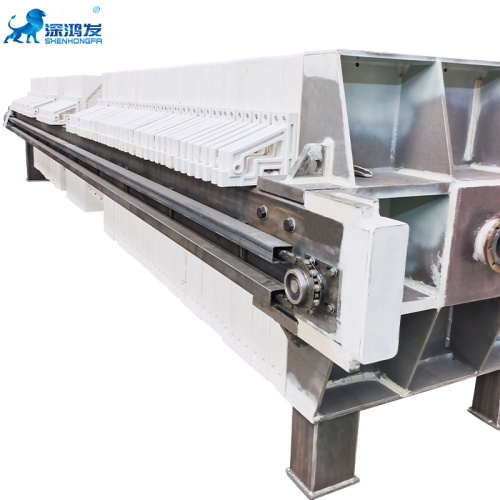

Features of Shenhongfa Filter Press:

1. Short working cycle and high efficiency.

2. Big capacity. Unique plate design makes filtrate discharge more smoothly to make higher processing capacity.

3. Good filtering performance. Our filter press can endure higher feeding pressure, so that get lowest cake moisture.

4. Low running cost. According to CE standard, our filter press has remarkable performance to decrease the running cost.

5. Filter plate are made of reinforced polypropylene with features of high strength, corrosion resistance, nontoxic and odorless.

6. According to your material we will recommend special filter cloth, which can improving the filtering accuracy and efficiency.

7. Main beam material is Q235B/Q345B, with sand blasting processing.

8. Hydraulic station adopt ABB motor ensure stable performance.

9. Hydraulic squeezing ensures no leakage to avoid secondary pollution.

10. Cabinet elements adopts international famous brands: Siemens Schneider etc.

PRODUCT SHOW

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

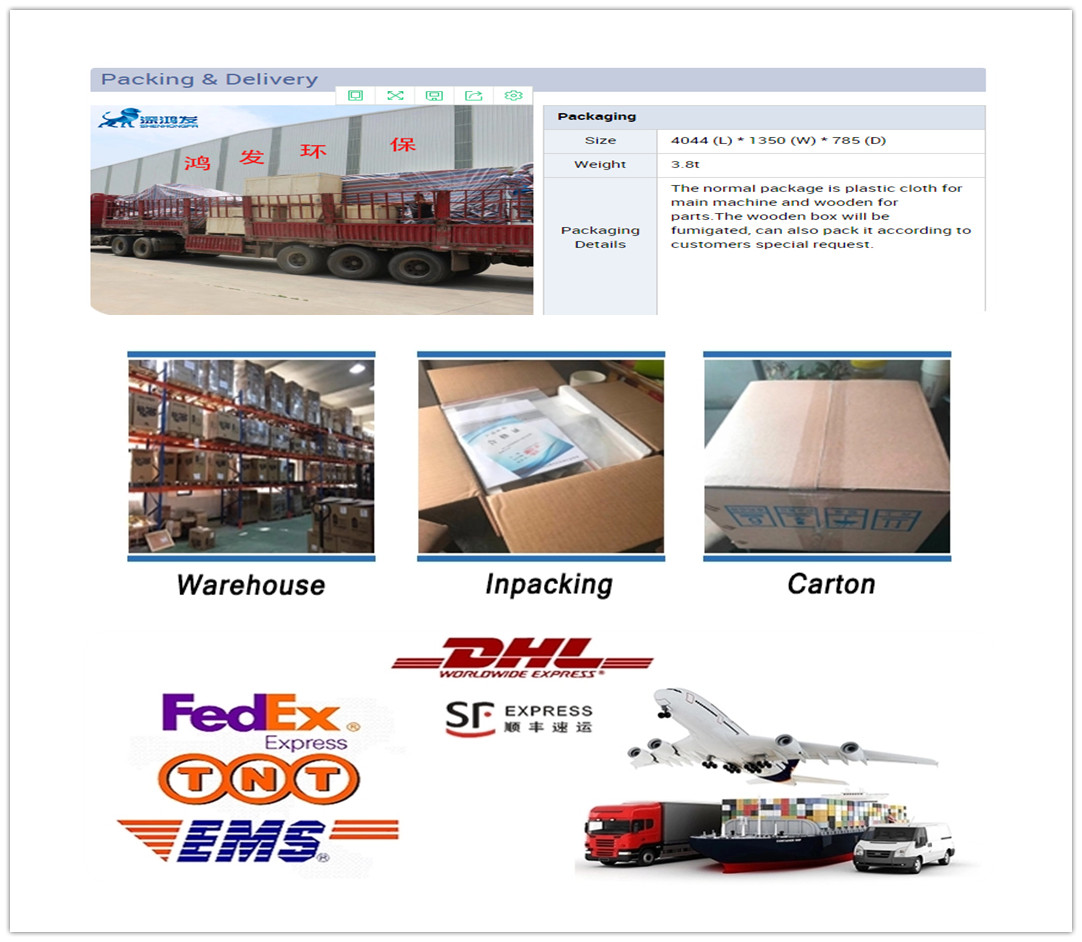

PACKING AND DELIVERY

Our Engineering Project

FAQ:

-------1. How to buy your interested products?

You can provide us the water sources, water quality, flow rate and ground area, material requirements about your project (More details, please contact us).

-------2. How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

-------3. What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 1 months.

-------4. How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

-------5. How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

-------6. How long is the validity?

The validity is 12 months after installation

Related Keywords