Chamber Filter Press for Sludge Dewatering for spin

-

$5000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212919.26 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

Plate And Frame Filter Press For Oil Fractionation

Introduction of Filter Press:

A filter press is a batch-operated, fixed-volume device with a volume ranging from 0.1m3 to 20m3 that uses pressure to separate liquids from solids. The slurry is pumped into the filter press and dewatered under pressure. The filter press is very versatile, it can be used for solid-liquid separation or wastewater treatment in various industries and applications, such as mining, metallurgy, petroleum, chemical industry, medical treatment, printing and dyeing, papermaking, food, alcohol, textile production, etc.

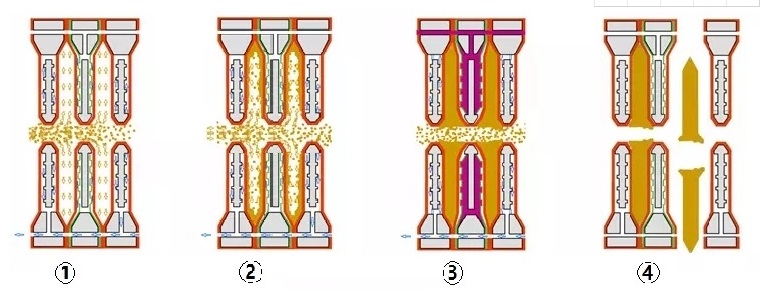

Working principle of Chamber Filter Press:

- 1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- 2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- 3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- 4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Why choose Shen HongFa Filter Press

We have professional team in sludge filteration which have many research staffs who have devoted themselves to the industry for more than 20 years, and our High-Efficiency Circular Filter Press for Sludge, saled all over the world.

1),Long history : our factory established in 2014,and we are the leading enterprise in filter press industry .

2),we are one of the main constitutor of press filter regulations.

3),we are a professional team which have many research staffs who have devoted themselves to the industry for more than 20 years.

4),We offer different material's filter plate according to different industry , while other providers couldn't make it .

5), Our products are sold to many companies which most of them are top500 .

6),We manufacture the filter plate ourselves , so we could guarantee its quality ,while other providers buy it from others.

Company Profile

Shenzhen HONGFA ENVIRONMENTAL PROTECTION EQUIPMENT CO.,Ltd has become one of the world's leading manufacturers of high-quality filter presses in the field of solid-liquid separation

It is a professional one-stop company covers develop,design,produce,sale and after-service,the company has a professional R&D team, and draws on the advance technology of the world on the products and innovates constantly Company also has environment protection equipment manufacturing factory and filter press accessories manufacturing factory.

The company specializes in filter equipment and related accessories,such as the series of plate and frame filter press,chamber filter press,membrane filter press ,cast iron filter press, stainless steel filter press,filter plate,filter cloth,water faucet and other accessories,filter press be widely used in petroleum,chemical, food ,pharmaceutical,paper making,coal washing , ceramics,mine and other sewage treatment industries

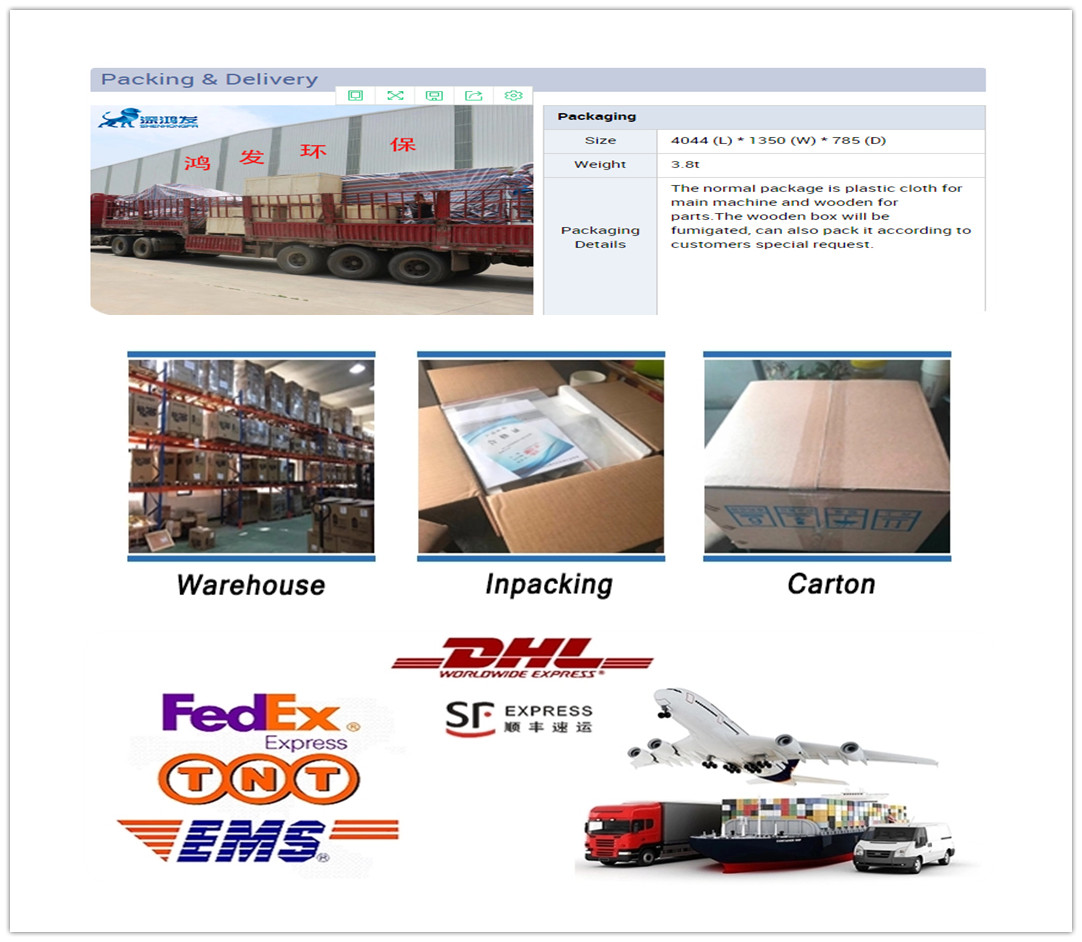

PACKING AND DELIVERY

Related Keywords