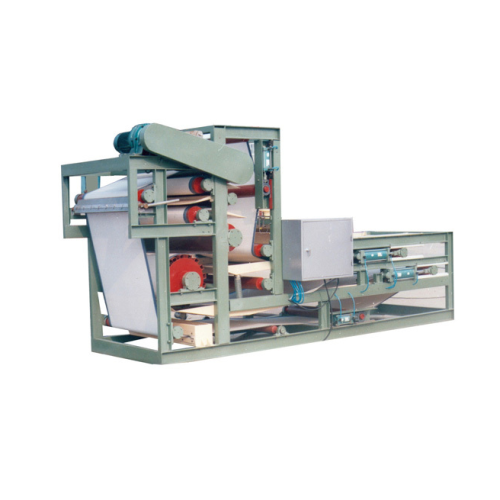

Shen Hongfa Belt sludge conveying filter press

-

$6000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 1000sets/month |

| Supply Ability: | 1000sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,Express Delivery,CFR,CIF,EXW,DES,DAF,DDU,DDP |

| Certificate: | ISO9001 |

| HS Code: | 842190900 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shenzhen,Qingdao,Shanghai |

What is a Belt Filter Press?

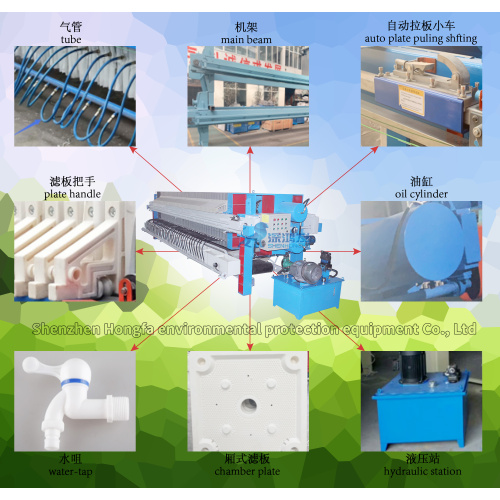

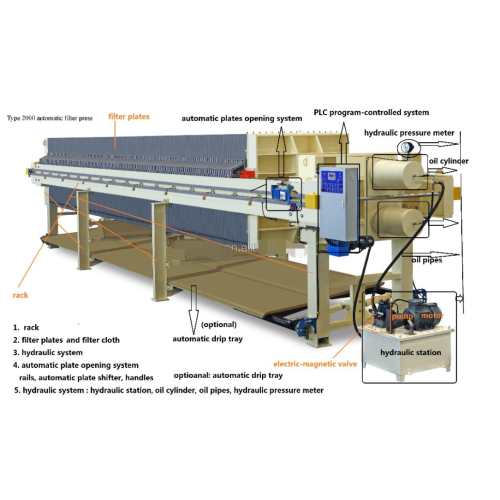

Shenzhen Hongfa Environmental Protection Equipment Co., Ltd. is an expert manufacturer of filter presses, with high quality and reasonable prices. All products have been inspected and meet environmental protection standards. The company's products are not only belt filter presses, but also other products such as box filter presses, stainless steel filter presses, cast iron filter presses, etc., and various accessories are also produced by our company, which truly integrates industry and trade. , Can provide customers with worry-free after-sales service. At present, the filter press produced by our company has been sold in large quantities in China and all over the world, and is widely used in sand field, coal washing plant, mineral processing plant, metal mine plant, sewage treatment plant, urban piling, sand washing and sand making plant, stone plant, Dewatering of sewage sludge in mine stone factories, mining plants, coal mines, piling mud, river dredging and other occasions.

Belt filter press installation and commissioning:

1. The host device is placed on the foundation, and the two sides correspond to the front and rear of the rack, and the left and right are different, and the unevenness is not greater than 3mm.

2. After the frame is corrected, use cement mortar (cement and sand 1:3) to pour the anchor screw holes, and moisturize and harden. After the cement solidifies, tighten the anchor nuts evenly in stages, and finally fill the gaps on the bottom of the machine with cement solid, and lightened.

3. Adjust each roller of the equipment so that its axis is perpendicular to the center plane of the frame. The non-parallelism of the axis of all rollers is not more than 2mm, and it is allowed to add pads for adjustment.

4. The filter belt device should be in place accurately and keep it straight.

Related Keywords