Press Filter for Municipal Waste Water Purifier

-

$20000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Others, Air, Express

- Port:

- SHENZHEN, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHNIA |

|---|---|

| Productivity: | 100SET/MONTH |

| Supply Ability: | 100SETS/MONTHES |

| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | CFR,FOB,DAF,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910 |

| Transportation: | Ocean,Land,Others,Air,Express |

| Port: | SHENZHEN,Qingdao,Shanghai |

1.Closing of the filter plates: when start the press button on the PLC control cabinet,the moving head plates will be activated by the hydraulic clamping the plates.

2.Filling: The sludge (or slurry) will be pumped into the chamber one by one. When all chambers are full off filter cake, the filtration is finished.

3.Filter opening: The moving head is drawn back to disengage the first filtration chamber. The cake falls will drop from the plates under gravity.

The auto pulling system pulls out the plates one by one

| Technical Specification | ||||||||||||

| Filtration Area(m2) | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 1000 |

| Filter Plate Number (pc) | 57 | 65 | 73 | 79 | 87 | 95 | 103 | 111 | 117 | 125 | 133 | 147 |

| Filter plate Thinkness (mm) | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Cake Thickness(mm) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Filter Chamber Volume (m³) | 5.8 | 6.6 | 7.4 | 8 | 8.8 | 9.6 | 10.4 | 11.2 | 11.8 | 12.6 | 13.6 | 14.8 |

| ☆Above data is for reference, and the actual data should subject to the confirmed order. | ||||||||||||

| Expansion device and options | |

| Filter Pressure | upto 2Mpa |

| Slurry temperature | normal temperature; high temperature |

| Filter plate material | PP ;high-temperature PP |

| Filter Plate types | membrane plate;CGR plate; plate and frame |

| Closure system | automated (electric hydraulic) |

| Control systems | standard relay control ; PLC control |

| Filter cake washing | water or airblow |

| Plate shifting operation | manual ;automatic |

| Frame structure | Sidebar design; overhead design |

| Frame material | mild steel; SS304;SS316L;mild steel with TPFE, |

| Frame color | As per customer request |

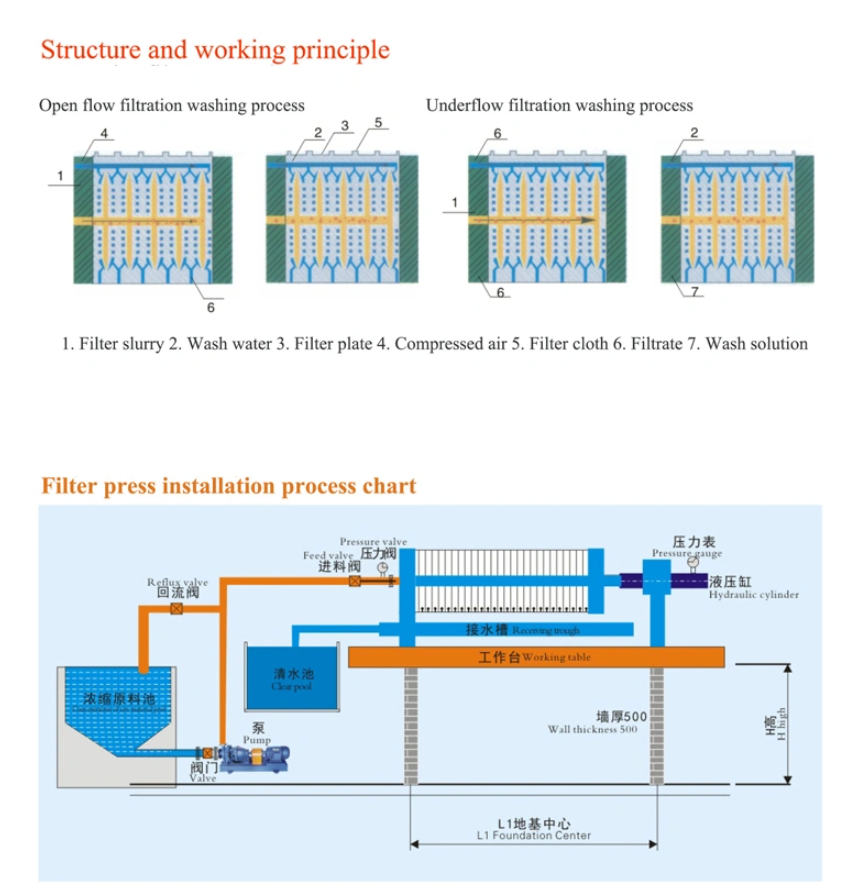

| Filtrate blowdown system | open/under current |

| Feeding option | Centre feeding/ corner feeding/two-side feeding |

| Corrosion resistance coating | Stainless steel, plastic coated, FRP coated,glass fiber coated, special paint |

| Expansion device | Drip tray device |

| Automatic cloth washer | |

| Automatic cake shaking system | |

| Filter cake hopper | |

| Filter cake conveyor | |

| cake carts | |

| cake chute | |

| elevated platform | |

| Feed pumps | Pneumatic diaphragm pump, progressive cavity pump, centrifugal pump, reciprocating pump,Screw pump |

| Safety device | splash curtain, safety guard, safety light curtains |

| Control panel display | Text displayer ; HMI |

| Core Blowback System | Yes |

| DCS | Yes |

| Explosion-proof applicaiton | Yes |

Before sale :

1.Your inquiry will be replied within 24 hours.

2.Help you to select suitable model.

3.Design totally according to your requirements

| Before we quote, please offer the bellow information: | |||||

| Name of liquid | Percentage of solid and liquid(%) | Specification gravity of solid | State of material | PH valve | Size of solid (mesh) |

| ? | ? | ? | ? | ? | ? |

| Temperature ºC | Recyclable liquid/solid | Moisture content in filter cake | Working hours/Day | Processing capacity/Day | is the liquid volatile or no |

| ? | ? | ? | ? | ? | ? |

After-sale service:

1.Provide 12 months warranty period and you will have our technical support within the filter press lifetime

Frequently asked questions

1.Q: Can you provide us the detailed drawing?

Yes, we can provide you the drawing after have made the prepayment.

2.Q: Are you a manufacturer or a trader?

We're a professional and experienced manufacturer located in HangZhou.

3.Q: Can you accept OEM?

Yes, we can produce the machinery according to your design standard.

4Q: How about the delivery time?

Normally 30 working days after prepayment, and we promise we will make the delivery as soon as we can.

Related Keywords