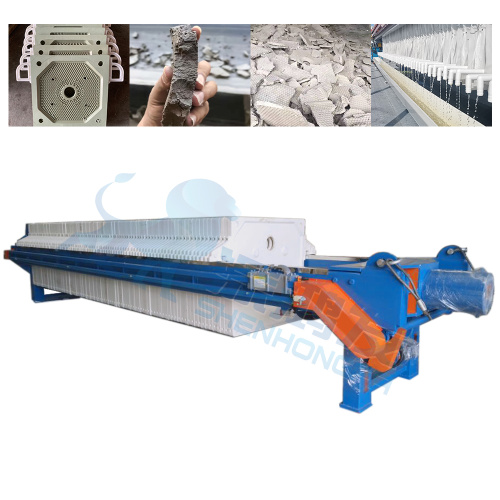

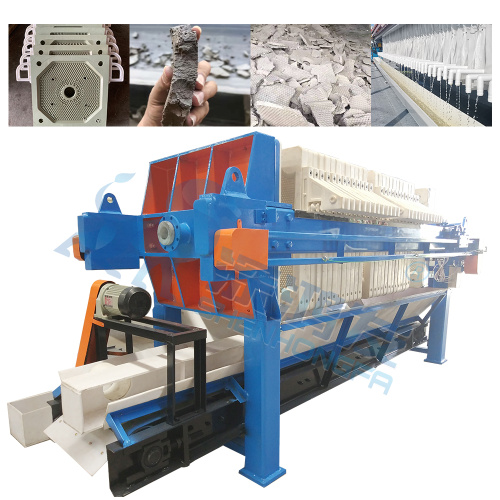

Manual Hydraulic Filter Press

-

$2500.001-2 Set/Sets

-

$2000.00≥3 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shenzhen, qingdao, shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shenzhen,qingdao,shanghai |

How to debug the filter press - sludge filter press

1. Switch the knob switch to the automatic position, press the "start" button switch, the hydraulic pump station starts to press the pressing plate, and automatically stops when the set pressure is reached. 2. The pneumatic feed valve will be opened automatically 3 seconds after the start of the hydraulic pump station. After the start of the feed valve, the sludge feed screw pump will start and the sludge will be pumped into the filter press for filtration. When the set pressure is reached, the filter press enters the pressure holding state. 3. After the end of the pressure retention, the press pneumatic valve is opened, and the medium water is injected into the press system for tympanic press. When the press parameters are set, the press pneumatic valve is automatically closed. 4. Open the blowoff pneumatic valve and empty the medium water in the filter plate. 5. After the press press is finished, the unloading step will be entered. The pulling plate trolley will pull the filter plate block by block, and the mud will be shoveled manually. 1. Before commissioning, equipment manufacturers in the sludge dewatering system should be present, such as screw pump, filter press, dosing system, electrical automation system, compressed air system and other relevant personnel to conduct joint commissioning, so as to ensure the smooth commissioning and operation of the sludge dewatering system. 2. Debugging tools: wrench, screwdriver, multimeter, cutting machine, welding machine, level. 3. Electrical connection shall be completed by electrician. The wiring of power supply and motor is correct, and the steering is consistent with the arrow in the direction of rotation. 4. Before the operation of the sludge feed screw pump, clean the pipeline in front of the pump and clean the particles larger than 3mm. 5. Check whether the sludge feed screw pump, diaphragm filter press, press water tank, press water pump, flushing water tank, flushing water pump, blowoff gas storage tank, instrument gas storage tank, freeze dryer, air compressor, sludge hopper, electromagnetic flowmeter, pressure sensor, pneumatic valve and manual valve are installed completely and meet the design requirements. 6. Check whether all pipes, flanges and valve bolts in the sludge dewatering system are tightened and whether welding points are in good condition to avoid water leakage during operation. 7. Pressure vessels, pumps, and air compressors are fully installed. 8. Check whether the vertical and horizontal of the filter press frame are horizontal, and the longitudinal and horizontal must be kept level. 9. Check whether the supporting leg of the thrust plate of the diaphragm filter press is fixed, whether the supporting leg of the frame is in a state of free displacement, check whether the opening of the flip plate and the position of the pit are correct, and ensure that the edge of the pit does not block the opening of the flip plate. Check whether the filter press frame is horizontal longitudinally and horizontally, and the longitudinally and horizontally must be horizontal. Check whether the installation of each process pipeline is in strict accordance with the construction drawings. 10. Check whether the diaphragm press filter plate installation number and arrangement sequence is accurate, strictly according to the stipulated process configuration of the filter plate can not be arranged at will, check whether the supporting filter plate balance pad is installed. The press cloth is installed in the same order as film assembly, and the aperture is the same. The single press cloth is installed correctly, the clip cloth lock is tight, and all press cloth is flat without folding. 11. Check whether the hydraulic system is installed correctly, the oil brand is accurate, the oil pipe connection is accurate, and the high pressure oil pipe connection is beautiful, without dead bending twist. 12. Check whether small accessories of each part of the main body of the equipment are missing or damaged. 13. Check whether the voltage used by the electrical system matches the on-site voltage, and notify the on-site customer supervisor of power supply before power-on to prevent electric shock accidents. When preparing to power on, ensure that all distribution switches in the cabinet are off. Use a professional electrician to measure the U/V/W/N phase sequence of the main power supply line using a multimeter. Do not power on the power supply blindly. 14. Preparation of reagents: according to the nature of sewage, select the appropriate product model through a pilot test in advance to ensure sufficient reagents; 2 hours in advance of the use does not contain suspended substances and inorganic salts neutral, low hardness of water configuration 0.2% concentration of PAM solution, preparation solution should not be stored for a long time, it is best to use now, solution storage should not exceed 24 hours.

Related Keywords