Automatic Plate And Frame Sludge Filter Press Machine

-

$4000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200sets/month |

| Supply Ability: | 200sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS,FCA |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

Automatic Plate And Frame Sludge Filter Press Machine

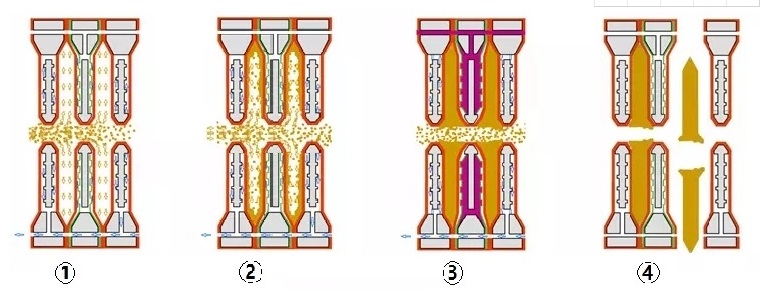

Sludge mechanical dehydration methods include filtration dehydration, centrifugal dehydration and pressing dehydration, filtration dehydration and vacuum filtration and pressure filtration; Centrifugal dehydration is the use of centrifuge dehydration; Press dewatering is done with a screw press or rolling press. Pressure filtration and centrifugal dehydration are commonly used. Sludge filtration dewatering is driven by the pressure difference between the two sides of the filtration medium, so that the sludge moisture is forced through the filtration medium to form filtrate, and the solid particles are intercepted on the medium to form filter cake, so as to achieve the purpose of sludge dewatering. Plate frame filter is the first applied in chemical dehydration machinery. It has the advantages of large filtration force, high solid content of filter cake, clear filtrate, high solid recovery rate, less consumption of conditioning drugs and so on. It is widely used in some sewage plants.

The design method of pressure filtration dehydration is mainly based on the sludge treatment capacity, dehydrated sludge concentration, filter press working procedure, filter pressure and so on to calculate the yield of mud cake, the required filter press area and the number of machines.

The dewatering area of plate frame filter press is calculated as follows:

Where, A- dehydration area of pressure filtration, m;

QS- Sludge amount per dewatering (sludge amount), m;

q- dehydration load, m/(m·h);

t- Each dehydration time, h.

According to the calculated dewatering area A, the plate and frame filter press is selected. At least 2~3 sets should be selected, and a full set of equipment should be arranged in the dehydration workshop.

Related Keywords