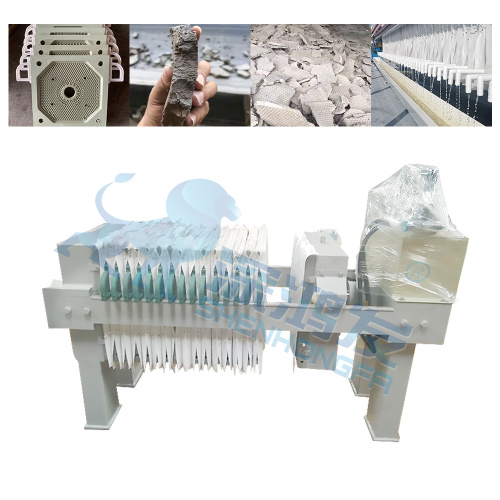

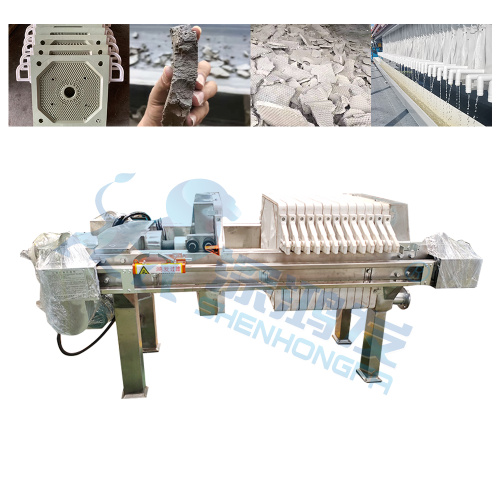

Plate and frame automatic pressure hydraulic filter press

-

$2764.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land

- Port:

- Qingdao, Tianjin, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Productivity: | 1000/m |

| Supply Ability: | 1000/m |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910 |

| Transportation: | Ocean,Land |

| Port: | Qingdao,Tianjin,Shenzhen |

How to use a plate frame filter press?

1. Preparation: Before using the plate and frame filter press, it is important to ensure that all the necessary components are present and in good working condition. This includes the filter press itself, the filter plates, and the filter cloths.

2. Assembly: The filter plates are placed on the filter press in alternating order, with a filter cloth placed between each plate. Once all the plates are in place, the filter press is tightened using a hydraulic or manual mechanism to create a seal.

3. Loading: The liquid to be filtered is then pumped into the filter press through an inlet port. The liquid is distributed evenly across the filter plates, which trap the solids while allowing the liquid to pass through.

4. Filtration: The liquid is forced through the filter cloth and out of the filter press through an outlet port, leaving behind the solids trapped between the filter plates.

5. Cleaning: Once the filtration process is complete, the filter press is opened and the filter plates are removed. The filter cloths are then cleaned or replaced, and the filter press is reassembled for the next use.

6. Disposal: The solids trapped in the filter plates can be disposed of according to local regulations. The filtered liquid can be further processed or used as desired.

Related Keywords