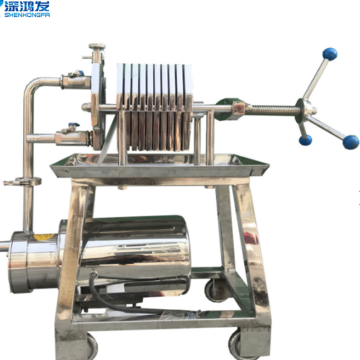

Small manual Laboratory filter press

-

$1400.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Tianjin, Shenzhen, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000sets/month |

| Supply Ability: | 3000sets/month |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CIF,EXW,FAS,FCA,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291076.31 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin,Shenzhen,Qingdao |

The filter press is a kind of equipment for solid-liquid separation of various sludge wastewater, and the sludge wastewater is what we call the material that is squeezed and dehydrated by the filter press. The properties of the material play an important role in the selection of the filter press type, why do you say that? Because some materials are acidic or alkaline, or are corrosive in other aspects, or have strong viscosity and are not easy to be filtered, then we usually recommend that users send me some samples of the material if conditions permit. If the company conducts tests, then a testing machine is needed here, which is a machine specially designed to test the filtration of materials, which will help users choose the most suitable filter press equipment.

Care should be taken to achieve:

1)Check whether the overall accessories of the diaphragm filter press are complete;

2)Check whether the overall connection is tight;

3)Check whether the filter cloth is folded or damaged;

4)Turn the switch of the membrane filter press to the "tight" position, move the piston rod forward, and press the filter plate tightly, and the membrane filter press will automatically enter the filter pressing state;

5)Open the sludge pump to feed, control the return valve to adjust the pressure;

6)Under pressure, the sludge is pressed into a mud cake. Under the normal pressure filtration of the diaphragm filter press, if there is little liquid from the filter press, stop the sludge pump;

7)Check the filter plate where the mixed liquid is found, and replace it as soon as possible if it is damaged;

8)Turn the switch of the membrane filter press to "loose".

Related Keywords