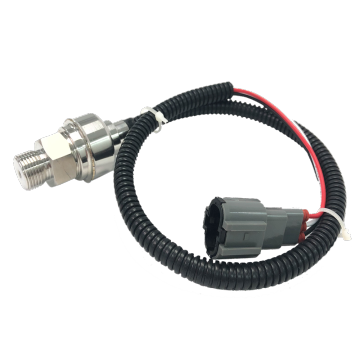

Accurate hydraulic high pressure sensor

-

$40.00≥200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Jiangmen, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong |

|---|---|

| Productivity: | 100000pcs/month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Jiangmen,Guangzhou,Shenzhen |

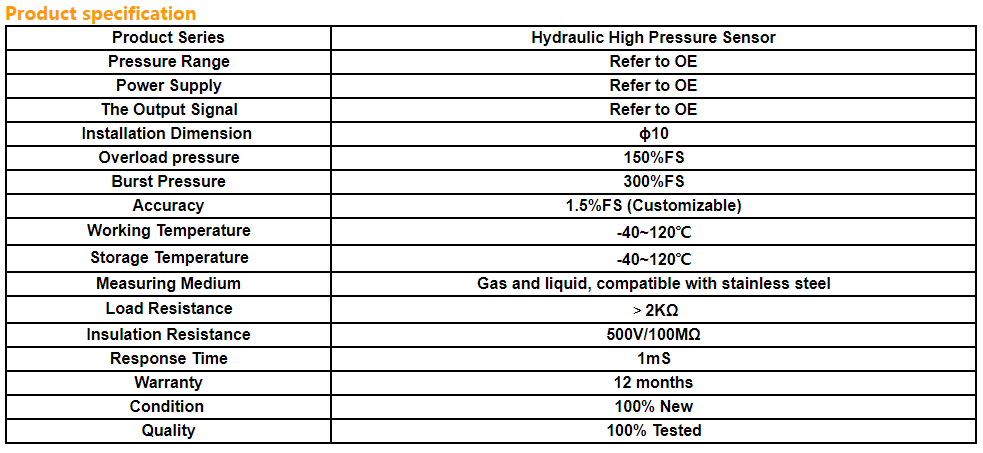

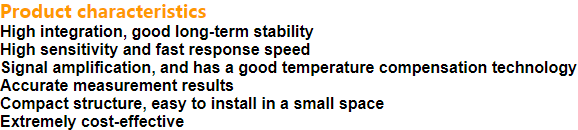

Product description

Improper wiring, incorrect polarity, short circuit, vibration/shock, misoperation, high temperature, overpressure/pressure spikes, chemical damage, etc., are some common problems. Typically, sensors are rugged devices designed for harsh environments. However, any defect of the hydraulic high pressure sensor will negatively affect its life and performance. As with all other component troubleshooting, the important factor required here is familiarity with hydraulic high-pressure sensors. Otherwise, contact technical support personnel. Whenever you detect any problems with hydraulic high pressure sensors, the main things you need to be aware of are installation and material compatibility. Later, as long as you have enough knowledge, you can check the internal parts and connections by dismantling them. Prevention is always more effective than troubleshooting or fixing. Here are some tips for eliminating sensor problems: prevent shock and vibration, avoid electrical interference, and eliminate voltage spikes. Professional manufacturing engineering hydraulic sensor, high precision pressure sensor, water pressure sensor, refrigerant pressure transmitter, air conditioning pressure transmitter, etc.

Related Keywords