Cnc Machining Cnc Turning

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- guangdong, shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | guangdong |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 1000 |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | guangdong,shenzhen |

A CNC lathe is one of the most widely used CNC machine tools. CNC lathes are mainly used for machining shafts, disks,s, and other rotary parts. Through the operation of the CNC machining program, it can automatically complete the internal and external cylindrical surface, conical surface, forming surface, thread, and end face, and other processes of cutting, and can carry out groove, drilling, reaming, reaming, and other work. The turning center can complete more processing procedures in one clamping, improving the processing accuracy and production efficiency, especially suitable for complex shape rotary parts processing.

Because the radial dimensions of these parts, whether measured dimensions or drawing dimensions are expressed by the diameter value, the CNC lathe adopts the diameter programming method, that is, when the absolute value is specified, X is the diameter value; When the relative value is used for programming, the programming value is twice the actual radial displacement of the tool. For different CNC lathes and CNC systems, the programming is basically the same, with individual differences, referring to the specific machine tool user manual or programming manual.

In recent years, machining with the improvement of product accuracy requirements, the application of CNC lathes is more and more common, CNC lathes with their high precision, and high efficiency can process difficult products of the characteristics of more and more favored by machining manufacturers. So, what are the characteristics and processing characteristics of CNC lathes?

The shape of a CNC lathe is similar to that of an ordinary lathe, that is, it is composed of a bed, headstock, tool holder, feed system, pressure system, cooling and lubrication system, and so on. The feed system of the CNC lathe is different from that of the ordinary lathe. The traditional lathe has a feed box and exchange gear frame, while the CNC lathe directly uses a servo motor to drive the slide plate and tool holder through a ball screw to realize feed movement, so the structure of the feed system is greatly simplified.

CNC lathe is a kind of high precision, high-efficiency automatic machine tool, is also the most used CNC machine tool, accounting for about 25% of the total number of CNC machine tools. It is mainly used for machining shafts, disks,s, and other rotary parts with high precision requirements, good surface roughness, and complex contour shape. It can automatically complete the cutting of cylindrical surfaces, conical surfaces, circular surfaces, and various threads through program control. It can be used for grooving, drilling, reaming, reaming, and other processing.

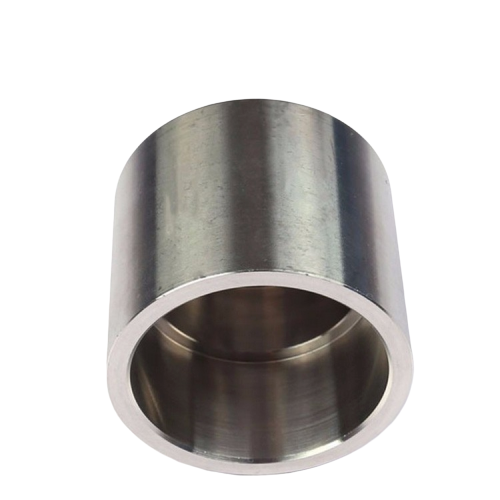

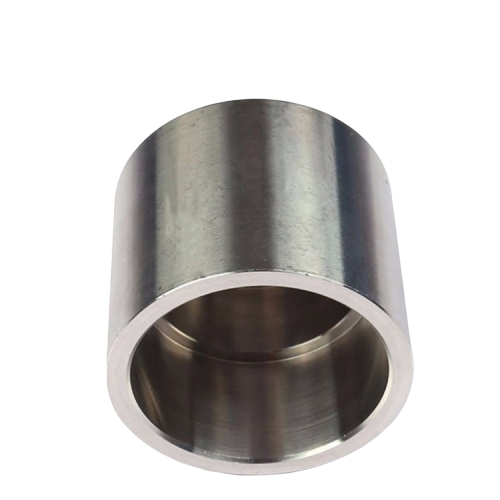

Product Description:

|

Product Name

|

Custom Stainless Steel Mechanical Part Titanium CNC Machining CNC Turning

|

|

Process

|

CNC machining ,CNC turning , CNC milling

|

|

Material

|

Aluminum,Stainless steel,Brass,Iron,Plastic,Nylon ,ABS, POM, PP, PC,PTFE, PEEK

|

|

Tolerance

|

+/-0.01mm

|

|

Surface

|

Chorme plated,Zinc plated,Anodized.Sand blasting ,Passivation ,PVD

|

|

Quality control

|

- First batch inspection:After production start or adjustment,test several parts.

- Cyclic inspection: Make a random inspection of the products Interval half hour. - Completion inspection: Inspection of semi-finished products or finished products after each process. - Pre-delivery inspection:Factory inspection is required for each batch of products and attach the test report. |

|

Application

|

OEM CNC Machining, Mining Accessories, Machinery Accessoried, Truck Parts, Auto Parts, Industrial Parts, etc

|

Photo Details:

Related Keywords