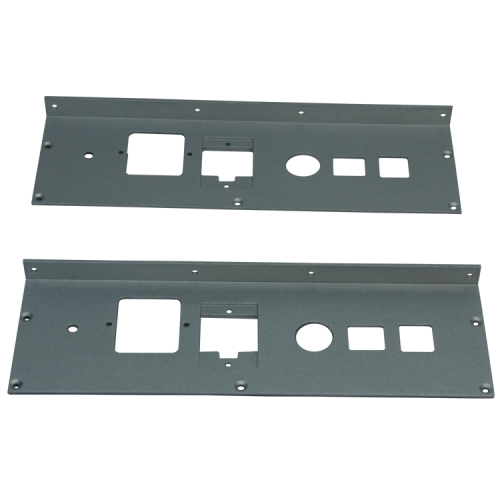

laser cutting tube service

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Full stroke automatic laser cutting blanking of large length metal pipe

For the process requirements of full stroke automatic laser cutting and blanking of long-length metal pipes, the double drive pneumatic chuck rotating mechanism (driving shaft W and driven shaft W1) is adopted in the mechanical structure, and the pneumatic chuck rotating mechanism of left driving shaft w axis is fixed to clamp the pipes, and the pipes are cut through the movement of machine bed x, y and W, The pneumatic chuck rotating mechanism of the right driven shaft W1 can move along the axial direction of the workpiece with the workbench, and can realize the full stroke automatic laser cutting and blanking of large-length metal pipes.

NC cutting technology

NC cutting is a large-scale, high-efficiency and high-quality cutting production mode of pipes. The core of NC cutting is NC cutting system. The cutting control software of the NC system provides advanced cutting technology and rich cutting experience, which can prevent many problems, such as over burning of the cutting point of the part, over burning of the corner of the part, inclination of the cutting surface, deformation or failure to close the circle when cutting circular parts.

Cutting operators can achieve high-quality and high-efficiency NC cutting by skillfully using the control system.

Professional pipe Nesting Technology

Due to the high cutting efficiency of NC laser tube cutting, programming nesting is more complex. If it is not used properly, it will cause pipe waste and low cutting efficiency. Through the professional pipe cutting and nesting software, the drawing, nesting and blanking are pre programmed on the computer to generate the NC cutting program, and then the full stroke automatic laser cutting and blanking of large-length metal pipes are carried out. Professional pipe nesting software is the basis and prerequisite for realizing large-scale, high-efficiency and high-quality cutting production of NC pipe cutting machine.

Pipe cutting process

When cutting the pipe (especially for the square pipe with small diameter), the dissolved slag is attached to the inner wall of the pipe, and most of the heat generated by cutting is absorbed by the workpiece. When the cutting density is large, the pipe is often overheated, and the corners and four corners of the square pipe are overheated, which seriously affects the cutting quality and even cannot be cut. To solve these problems: (1) the laser cutting head with height sensing servo system can ensure that the height between the cutting nozzle and the surface plane of the workpiece remains unchanged (the focus remains unchanged) during the cutting process, so that the cutting effect will not be affected by the change of the workpiece surface; (2) Method of increasing oxygen pressure (6-8mpa); (3) Improve the sharp angle synthesis speed through software. The above methods can solve the problems of "overburning" and slag hanging in pipe cutting.

Laser tube cutting technology is in the process of rapid development and continuous improvement. With the continuous updating and development of computer technology, mechanical structure, cutting technology and optimization algorithm, NC laser tube cutting technology will more prominently show its intelligent, fast and optimized cutting process and technology, so as to provide high-efficiency and high-quality cutting for laser tube cutting machine, and save pipe and energy consumption, Provide technical guarantee.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly, and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords