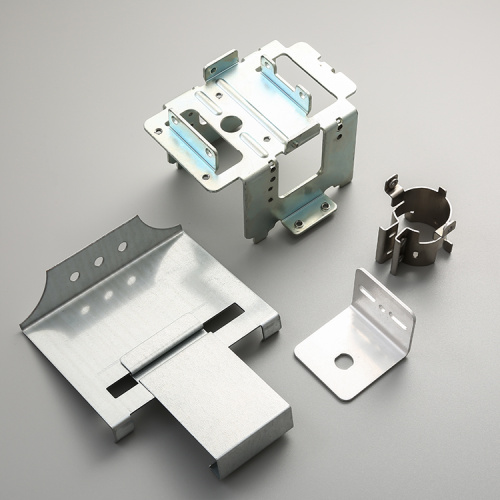

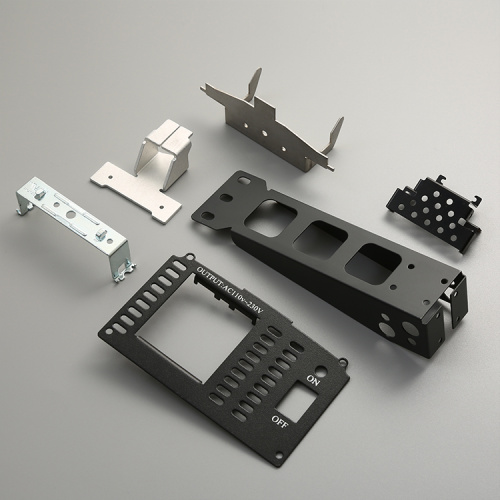

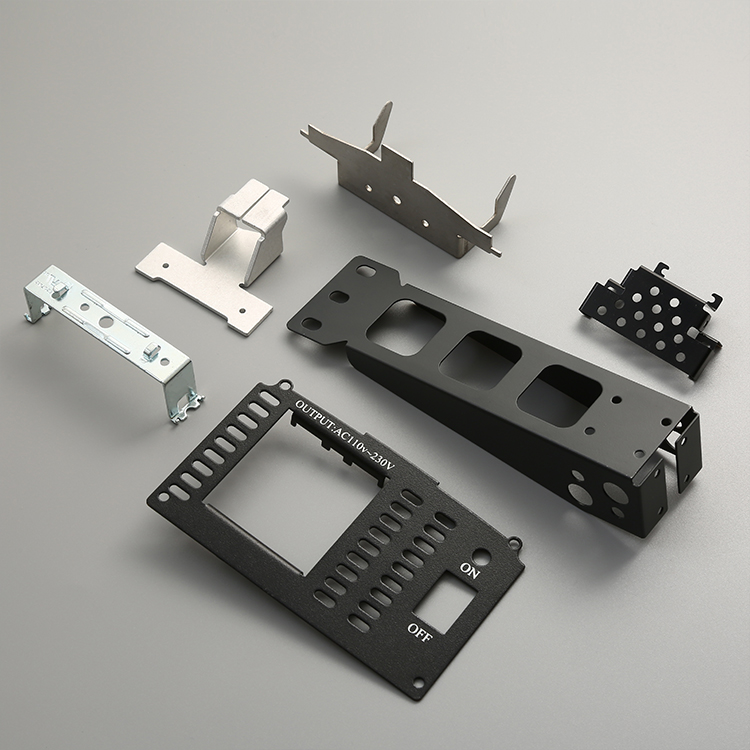

oem custom laser cutting parts

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Three kinds of laser cutting process

Flame cutting: Flame cutting is a standard process used when cutting low carbon steel. Flame and various oxygen are used as cutting gas. Oxygen is pressurized to up to 6bar and blown into the incision. There, the heated metal reacts with oxygen: it begins to burn and oxidize. The chemical reaction releases a huge amount of energy (up to five times that of the laser) to help the laser beam cut.

Flame cutting: makes high-speed cutting possible and can cut thick plates, such as low carbon steel over 30mm thick. However, this process also has the disadvantage that the cutting edge is covered by an oxide layer. The oxide layer must be removed before the parts are painted or matte, otherwise, the paint and coating will not adhere to the surface, without a protective coating, the parts will not resist corrosion.

Melt cutting: Melt cutting is another standard process used when cutting metal. But it can also be used to cut other fusible materials, such as ceramics. Here nitrogen or argon is used as the cutting gas, and the air pressure is blown from 2-20bar through the cut. Argon and nitrogen are inert gases, which means they don't react with the molten metal in the cut, just blow it away towards the bottom. At the same time, inert gas can protect the cutting edge from air oxidation.

Nitrogen can be used on almost any metal, especially titanium. Titanium reacts violently with oxygen and nitrogen, so argon is used to cut the titanium. The great advantage of melt cutting is that there is no oxide layer at the cutting edge and no further treatment is required. However, the laser beam needs to provide all the energy used for cutting. For this reason, the cutting speed of flame cutting can only be achieved when cutting very thin sheets. Melting a perforation is also difficult, and some cutting systems allow you to use oxygen puncture material and then use nitrogen to make the cut.

Compressed air cutting | for some people who don't want to purchase cutting gas, compressed air can also be used to cut sheets. Pressurized air to 5-6bar is sufficient to blow away the molten metal in the cut. Because nearly 80% of the air is nitrogen, compressed gas cutting basically belongs to melting cutting. On the surface, compressed air cutting seems to offer an economical alternative to nitrogen, since air is free. However, you have to compress the air, dry it, and remove any oil that might be present.

With all this in mind, a more realistic picture emerges of whether nitrogen is cost-effective. The air pressure and laser power achieved by the air compression system determine the thickness of the material that can be cut. For example, a 5kw laser and 6bar of compressed air can cut a 2mm thick plate with no rough edges. In general, the cutting edge is rougher than that of nitrogen melting cutting, and the air-assisted cutting has the best effect on aluminum.

Sheet metal processing in the past is still the main object of laser cutting. Laser cutting has obvious advantages over traditional methods when the object is flat, bulky, or shaped. Not only sheet metal, but lasers can also cut a variety of other materials, such as plastics, glass, ceramics, semiconductors, as well as textiles, wood, and paper. There are many different types of applications. Not only for thick, solid, and large parts but fine machining and micro-machining are also actually very popular.

Product Details:

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

FAQ:

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords