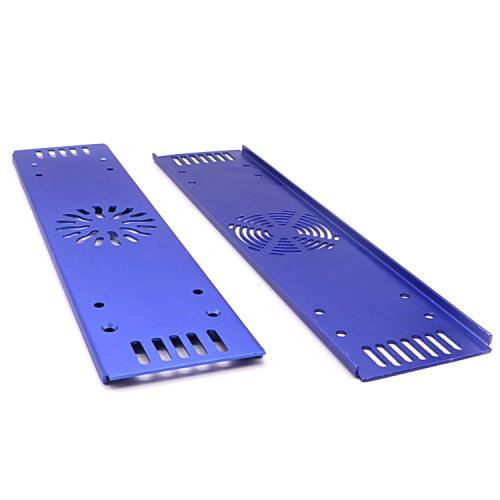

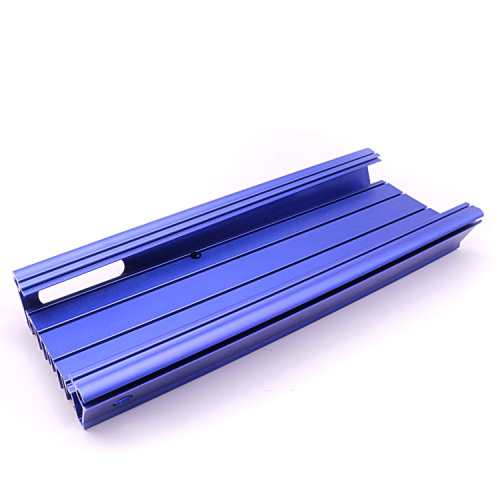

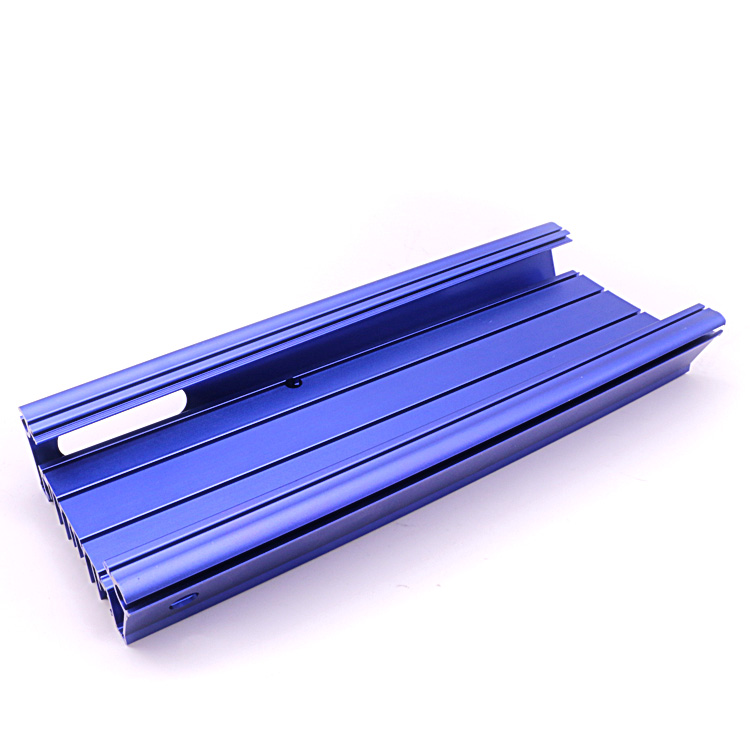

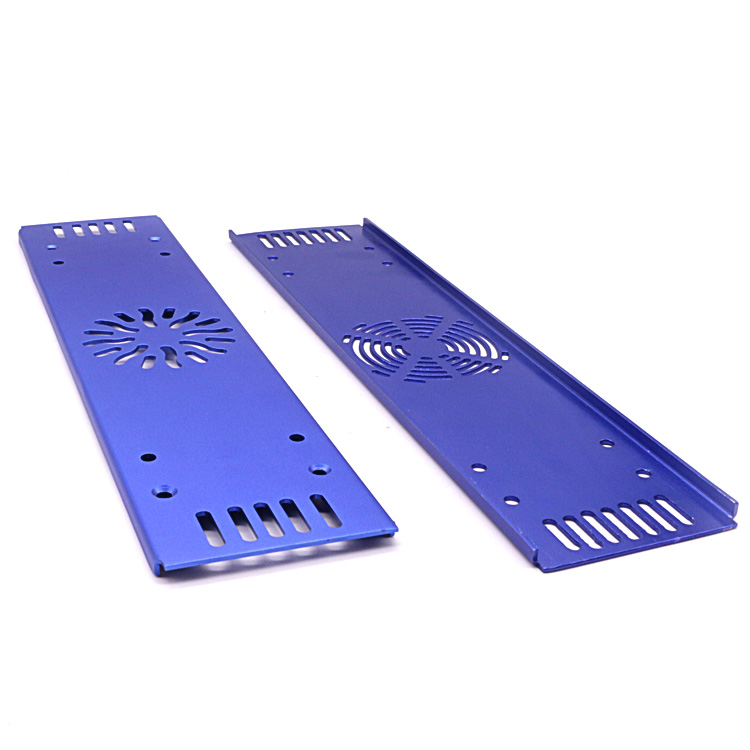

Custom sheet metal housing fabrication

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

sheet metal housing fabrication is processed by stamping mold, the subsequent process of sheet metal stamping products is through tapping, deburring, chamfering, riveting, anodic oxidation, packaging, OEM metal stamping products, sheet metal can be used for electronic and electrical manufacturing precision parts, help in the field of communication, for the production of automobile manufacturing process car shell body, In addition, it is also used in the production and manufacturing of medical instruments. szBERGEK is a professional sheet metal parts manufacturing factory, we can professionally design and manufacture all kinds of high-quality sheet metal parts stamping products, we have much-advanced equipment and a professional team, professional customized sheet metal processing products.

Sheet metal processing process characteristics

sheet metal fabrication belongs to thin steel, so it is relatively light in quality. Sheet metal processing through cold processing technology, so there is a relatively large strength, very hard. In addition, sheet metal belongs to steel, can pass an electric current, has good conductivity. And in the price compared to other steel processing methods have good cost performance.

During the processing will be through the shearing press, punch, CNC blanking, and other ways to complete the operation. Shears are sheet metal cut to meet the requirements of the material, in this operation can only be completed without hole processing. The punch can cut materials into different shapes and sizes. The advantage of this process is to saves time and improves productivity. During sheet metal processing, it can also be operated by laser blanking and sawing machines.

Q&A

1. What are the commonly used materials?

Aluminum, carbon steel, low carbon steel, stainless steel, other metals

2, sheet metal processing thickness is how much?

It depends on your product to customize

3. What are the specifications?

Customized according to your drawings

4. What format does the drawing file support?

2D: DWG, DXF, and PDF

3D: ASM, IGS, STEP, STp. ETC

Custom product case pictures:

click request quotation

Related Keywords