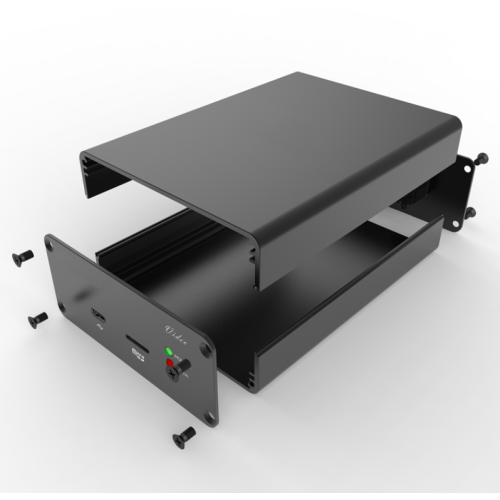

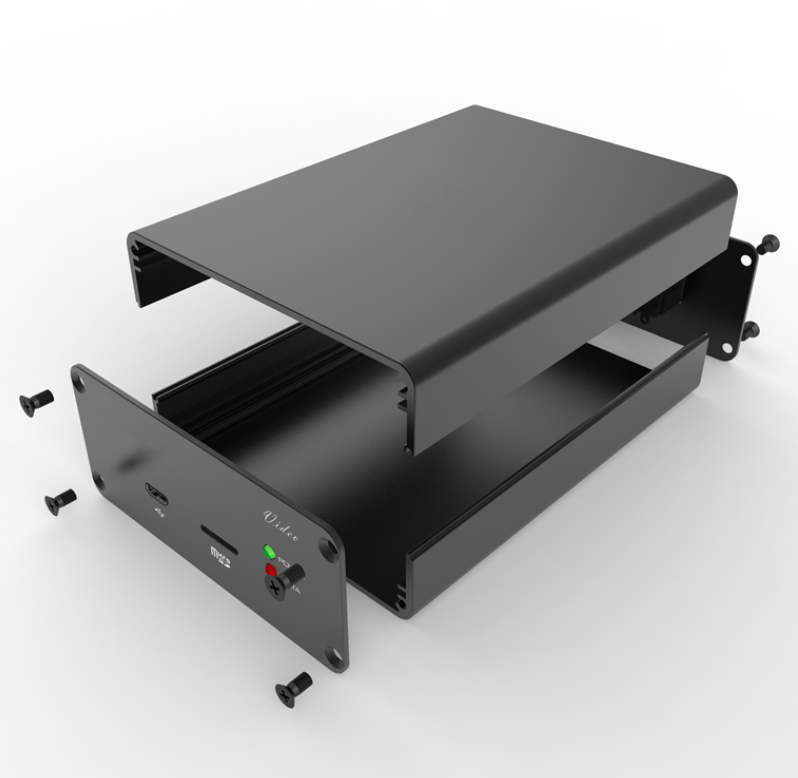

custom sheet metal fabrication service shenzhen

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Sheet metal processing is the key technology that sheet metal technicians need to master, and it is also an important process of sheet metal product forming. It includes not only the traditional cutting and blanking, blanking, bending forming and other methods and process parameters, but also various cold stamping die structures and process parameters, various equipment working principles and operation methods, as well as new stamping technology and new process.

Sheet metal processing is called sheet metal processing. Specifically, for example, the use of plates to make chimneys, iron barrels, oil tanks, oil pots, ventilation pipes, large and small ends of elbows, round places, funnel-shaped, etc. the main processes are shearing, bending, edge buckle, bending forming, welding, riveting, etc., which requires certain geometric knowledge. Sheet metal parts are sheet metal parts, that is, parts that can be processed by stamping, bending, stretching and other means. A general definition is parts with constant thickness in the processing process.

Sheet metal equipment:

Correspondingly, casting parts, forging parts and machined parts usually refer to metal cutting, that is, cutting tools are used to cut off the excess metal layer from the metal material (blank) or workpiece, so as to make the workpiece obtain a processing method with certain shape, dimensional accuracy and surface roughness. Such as grinding, milling, broaching, etc. In metal technology, corresponding to hot processing, cold processing refers to the processing technology that causes plastic deformation of metal below the recrystallization temperature, such as cold rolling, cold drawing, cold forging, stamping, cold extrusion, etc. Cold working deformation resistance is large. While forming the metal, work hardening can be used to improve the hardness and strength of the workpiece, but the plasticity will be reduced. Cold working is suitable for machining metal parts with small section size and high requirements for machining size and surface roughness.

Related Keywords