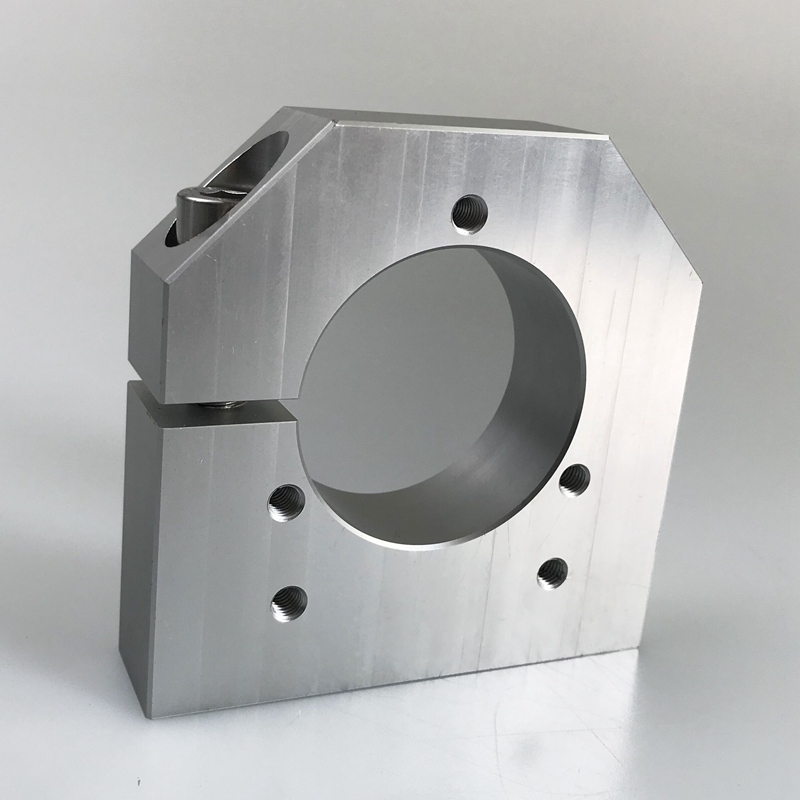

Precision oem stainless steel cnc machine parts

-

$6.50≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 800000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | NON |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Knowledge About CNC Machining

CNC (computer numerical control) is a subtractive manufacturing process which employs computerized controls and machine tools to remove layers of material from workpiece to get custom shapes and designs. While the CNC machining process offers various capabilities and operations, the basic 4 stages as following: Design CAD model - CAD file conversion - Setup CNC machine - Machining operation execution

CAD Model Design

The CNC machining process begins with the creation of a 2D vector or 3D solid part CAD design. The CAD software allows designer to produce a model or rendering of their parts along with the necessary technical specifications, such as dimensions and geometries.

Once the CAD design is completed, the designer exports it to a CNC-compatible file format, such as STEP or DXF.

CAD File Conversion

The formatted CAD design file runs through CAM software to extract the geometry of the custom-designed part and generates G-code which will control the CNC machine and manipulate the tooling to produce the custom-designed part.

The operator need to loads the CNC program to the machine once it is generated.

Machine Setup

Before running CNC program, the operators must prepare the machinery for operation which include affixing the workpiece onto machine spindles or workholding devices, and attaching the required tooling, such as drill bits and end mills, to the proper machine components. Once the machine is fully set up, the operator can run the CNC program.

Machining Operation Execution

The CNC program submits machine commands that indicate the actions and movements of the tools to the integrated computer of the machine, which operates and manipulates the machine tooling.

Initiating the program prompts the CNC machine to start machining process, and the program will guide the machine in the process of performing the necessary operations to produce custom-designed parts or products.

Knowledge About CNC Machining

CNC (computer numerical control) is a subtractive manufacturing process which employs computerized controls and machine tools to remove layers of material from workpiece to get custom shapes and designs. While the CNC machining process offers various capabilities and operations, the basic 4 stages as following: Design CAD model - CAD file conversion - Setup CNC machine - Machining operation execution

CAD Model Design

The CNC machining process begins with the creation of a 2D vector or 3D solid part CAD design. The CAD software allows designer to produce a model or rendering of their parts along with the necessary technical specifications, such as dimensions and geometries. Once the CAD design is completed, the designer exports it to a CNC-compatible file format, such as STEP or DXF.

|

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Related Keywords