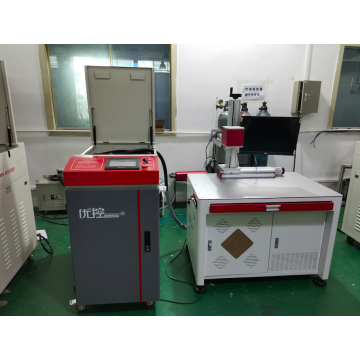

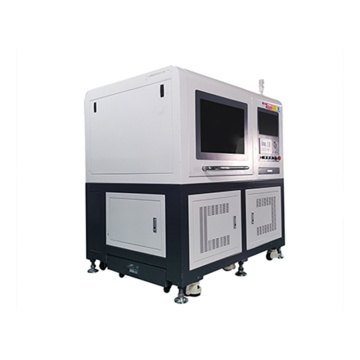

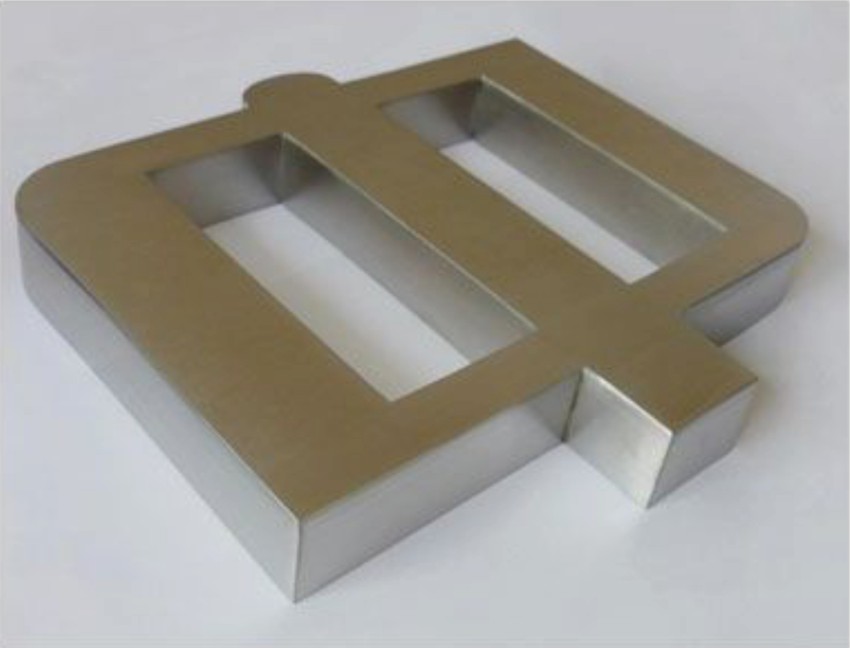

laser welding machine for stainless steel

-

$20000.00≥10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Min. Order:

- 10000 Set/Sets

- Transportation:

- Ocean, Land, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Express |

Summary information

The laser power supply first lights the pulse xenon lamp, discharges the xenon lamp pulse through the laser power supply, and forms a certain frequency and pulse width light wave. The light wave radiates to the Nd3 +: YAG laser crystal through the concentrating cavity, and then excites the Nd3 +: YAG laser crystal to emit light. After the resonance of the laser cavity, the 1064nm pulse laser is emitted. The pulse laser is expanded, reflected and excited (or through optical fiber transmission) focus and hit on the workpiece to be welded; Under the control of PLC or industrial PC, the numerical control platform is moved to complete the welding. The frequency, pulse width, waveform, table speed and moving direction of the pulse laser needed in welding can be controlled by single chip microcomputer, PLC or industrial PC. the pulse laser can be controlled by different settings of laser frequency and pulse width

Features and applications:

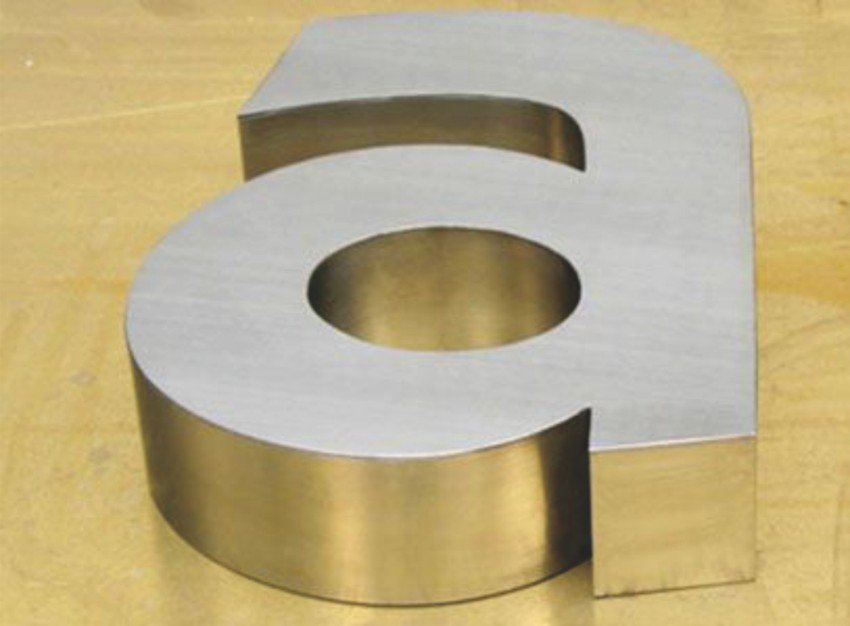

1. it has high ratio of depth to width, small weld width, small heat affected area, small deformation and fast welding speed;

2. the weld is flat and beautiful, and it is unnecessary to deal with it or simply handle the process after welding;

3. the weld has high quality and no porosity, which can reduce and optimize the impurities of the base metal. After the tissue welding, it can be refined. The strength and toughness of the weld are at least equal to or even more than the base metal;

4. it can be controlled accurately, the focus light point is small, and the positioning can be high-precision, and it is easy to realize automation;

5. welding between different materials can be realized;

6. it can realize spot welding, butt welding, overlapping sealing welding, etc.

Application Industry:

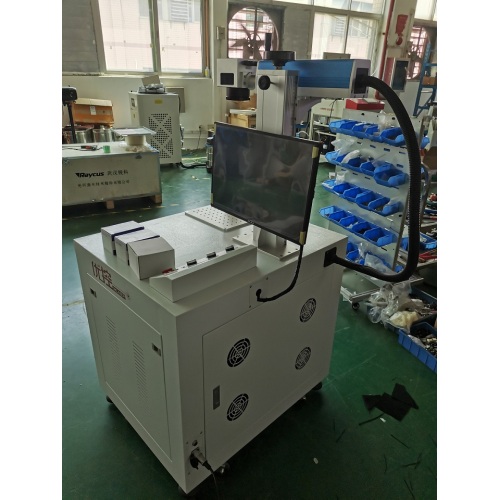

Pb80 has the advantages of good beam, fine spot, strong penetration ability, flexible installation and remote control operation. For the small energy spot welding, low average power and high-speed spot welding are especially suitable. It is suggested to be used with the high-speed scanning welding table of galvanometer to maximize the characteristics of high-speed spot welding. The fields of wide application include mobile phone shell, mobile phone shielding layer, welding of soft PCB in LCD, welding of optical fiber connector, micro electronic components, medical devices and other precision parts.

|

Model

|

UK-HJLX-SC500W |

UK-HJLX-SC1000W |

UK-HJLX-SC1500W |

|

laser power

|

500w |

1000w |

1500w |

|

Laser wavelength

|

1070±5nm |

1070±5nm |

1070±5nm |

|

Operation mode

|

Continuous / modulation |

||

|

Output welding joint type |

Hand held swing head + welding head |

||

|

Output power stability |

<3% |

<3% |

<3% |

|

Power regulation range |

10~100% |

10~100% |

10~100% |

|

Weld penetration

|

0.5~2.0mm |

0.5~2.5mm |

0.5~3.5mm |

|

Cooling mode |

Built in water cooling |

Built in water cooling |

Built in water cooling |

|

Fiber line length

|

Holding 10 meters, fixed head 15 meters

|

Holding 10 meters, fixed head 15 meters

|

Holding 10 meters, fixed head 15 meters

|

|

Blowing protection

|

Argon, nitrogen |

Argon, nitrogen |

Argon, nitrogen |

|

Electricity demand

|

Single phase AC220 V / 50 Hz |

AC220V/380V/50Hz |

Three phase AC380V / 50Hz |

|

Equipment power |

3.5Kw |

4.5Kw |

5.5Kw |

|

area covered

|

1*1.6m |

1*1.6m |

1*1.6m |

|

Overall weight

|

180Kg |

200Kg |

200Kg |

|

working temperature |

0~40℃ |

0~40℃ |

0~40℃ |

|

Working humidity |

10~75% |

10~75% |

10~75% |

|

Environmental needs

|

No vibration, no interference source, keep ventilation |

||

|

Consumables

|

Purified water, argon

|

Purified water, argon

|

Purified water, argon

|

Processing products

Related Keywords