Fiber Glass Compressed Air Filter With Warranty

-

$433.001-19 Piece/Pieces

-

$411.00≥20 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Ningnbo, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 500pcs per day |

| Supply Ability: | 500PCS Per Days |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,EXW,CIF,CFR |

| Certificate: | CE |

| HS Code: | 8421399090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Ningnbo,Qingdao |

We know that compressed air has become the second largest energy source besides electricity, and more and more companies cannot do without compressed air.

So you need a compressed air filter, but how to select the most situable compressed air filter for your application? Let's figure out the filter type.

Filter Type

①Particulate compressed air filters are used to remove dust and particles from the air.

②Coalescing filters are used mainly to capture oil and/or moisture that is suspended in the compressed air in very tiny droplets.

③Activated carbon filters remove (oil) odors and vapors.

Please think about below point before to source a new compressed air filter.

| ①Assess the requirements of your application. Different industry require different solution. | ③Any specific micron of filtration performance you required? | |||||||

| ②What type of filtration is needed? Coalecent filter material removes solid and liquied contaminants from gas streams. Particulate filter media removes solid from gas streams. Absorber media removes hydrocarbon vapors from gas streams. | ||||||||

| ④What are the working conditions of your application? Mainly criteria of consider : Flow, working pressure, temperature,pressure loss,material of structure (stainless steel, aluminum alloy, mild steel, carbon steel) | ||||||||

| ⑤Filter flow rate from how much SCFM? Pressure drop should be less than **bar? For saving the cost and protect environment. | ||||||||

FEATURE & BENEFIT

Rated working condition from temperature 1.5ºC~80ºC.Maxi. Pressure is 1.0Mpa. Air filter case with 15 years warranty.

Element with 6000~8000 hours lifespan, filtering performance up to 99.999%

Integrated die-casting filter up to RC 3 ", flow rate up to 37.2m³/min.

Alternative for Domnick Hunter Oil X Plus Series.

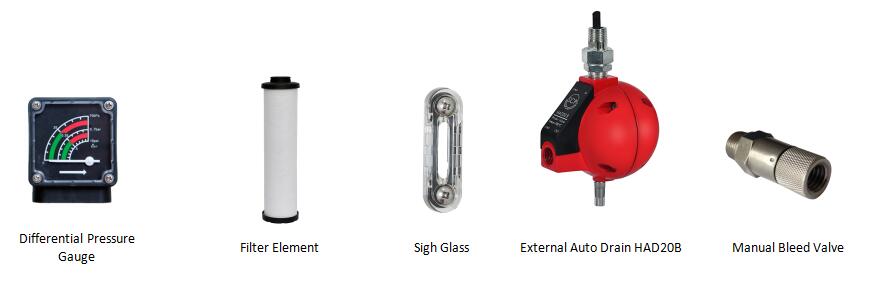

Configuration: Differential Pressure Indicator, Sight Glass, Auto Drain Valve.

Filter Element Grade

Filtration Grade

PF

AO

AA

AX

ACS

AR

AAR

Particle removal (ISO12500-3)

5μm

1μm

0.01μm

0.01μm

-

1μm

0.01μm

Outlet oil aerosol concentration (ISO12500-1)

5mg/m³

0.6mg/m³

<0.01mg/m³

<0.001mg/m³

<0.004mg/m³

-

-

Filtration performance of Particle (ISO12500-3)

-

99.999+%

99.999+%

99.999+%

99.999+%

99.999+%

99.999+%

Filtration performance of (ISO12500-1)

50%

80+%

99.9+%

99.99+%

-

-

-

Element spanlife

6000 hours

6000 hours

6000 hours

6000 hours

2000-3000 hours

4000-6000 hours

4000-6000 hours

Precede with

Before refrigerated air dryer

after air dryer

after AO

after AA

before AX

after desiccant dryer

after AR

The flow rate below is the treatment capacity of compressed air under rated working pressure 7 barg (100psi g).

For application in other working pressure, please refer to the correction factors.

Model

Pipe size

Flow rates

Dimension (mm)

L/S

m³/min

scfm

W(Width)

D (Depth)

H (Height)

A

B

C(clearance for housing)

YD017

RC1/2"

16.7

1.0

35.3

89

79

246

40

186

118

YD025

RC3/4"

25.0

1.5

53.0

89

79

246

40

186

118

YD030

RC1/2"

30.0

1.8

63.6

89

79

280

40

220

158

YD035

RC3/4"

33.3

2.0

70.6

89

79

280

40

220

158

YD058

RC3/4"

46.7

2.8

98.9

120

110

377

55

276

195

YD068

RC1"

60.0

3.6

127.1

120

110

377

55

276

195

YD080

RC1"

80.0

4.8

169.5

120

110

477

55

377

290

YD145

RC1-1/2"

120.0

7.2

254.2

120

110

477

55

377

290

YD220

RC2"

200.0

12.0

423.7

162

151

676

64

566

480

YD260

RC2-1/2"

233.3

14.0

494.4

162

151

676

64

566

480

YD330

RC2"

267.2

16.0

564.8

162

151

984

64

875

780

YD360

RC2-1/2"

317.3

19.0

670.7

162

151

984

64

875

780

YD405

RC2-1/2"

367.4

22.0

776.6

200

189

757

78

634

560

YD430

RC3"

467.6

28.0

988.4

200

189

757

78

634

560

YD620

RC3"

620.0

37.2

1313.6

200

189

1012

78

889

780

Technical requirements

Maximum operating pressure: 10 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C

| Pressure | Barg | 1 | 2 | 3 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

Compressed Air Filter Parts in Detail

Success Cases

Related Keywords