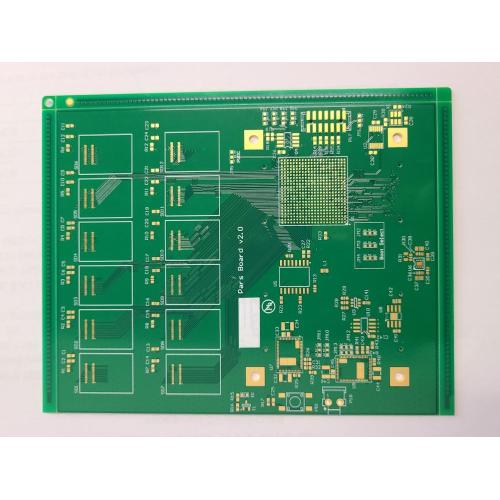

12 Hours quick turn pcb service

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal,Others |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FAS,DDP,DEQ |

How to use FR4 pcb?

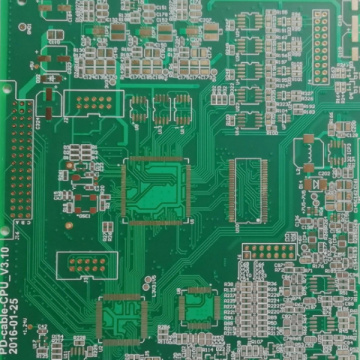

Using the correct thickness of the material is very important for constructing FR4 PCB. Thickness is measured in inches, such as thousands, inches or millimeters. There are several things to consider when choosing an FR4 material for your PCB. The following tips will simplify your selection process:

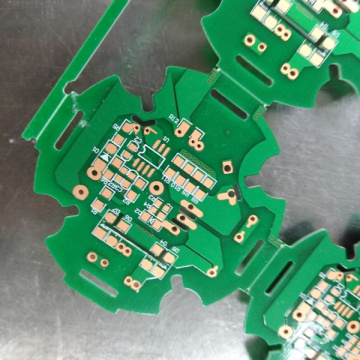

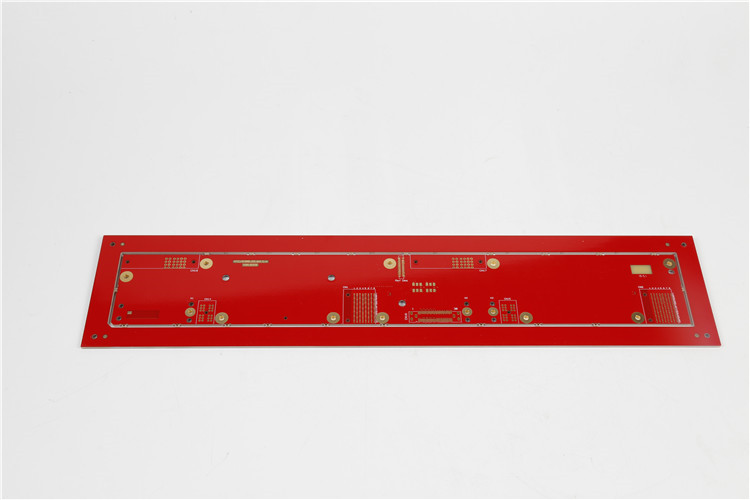

Select thin FR4 materials for building panels with space constraints. The thin material can support the various sophisticated components needed to build the device, such as Bluetooth accessories, USB connectors, etc. They are also useful for large projects where engineers want to focus on space-saving designs.

Thin FR4 materials are suitable for applications requiring flexibility. For example, using thin materials for automotive and medical PCBs is ideal because these need to be bent periodically.

Avoid choosing thinner materials for PCB designs with grooves, as this increases the risk of damage or board breakage.

Thickness of the material can affect the weight of the printed circuit board and may affect component compatibility. This means that the thin FR4 material would logically facilitate the creation of lightweight circuit boards, leading to the production of lightweight electronics. These lightweight products are attractive and easy to transport.

Related Keywords