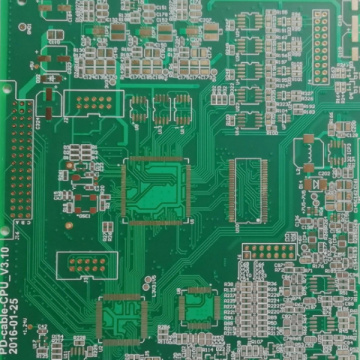

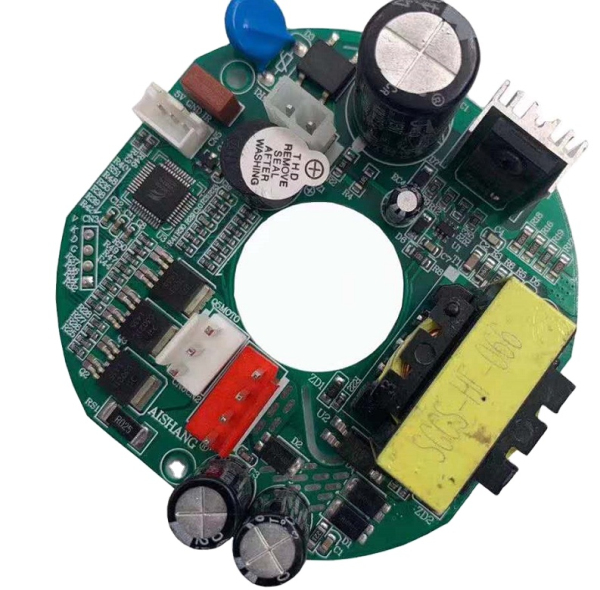

stand pedestal fan power supply contro pcba

-

$0.02≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact Now

How do you test a control board?

When PCBA suddenly stops working, there are sometimes obvious signs of failure. You need to rely on your own vision to find faulty Surface-Mount (SMT) &BGA Assembly or disconnection. Usually, circuit boards deployed in the field will be damaged by power surges, and there are obvious signs on the PCB.

Look for burned areas, especially on power modules or Cable Connectors I/O Connectors and connection ports. Pay attention to broken ICs, broken wires and blown out of Electronic Components. Sometimes, you can try to find damaged components through the pungent smell.

Check the industrial control PCB

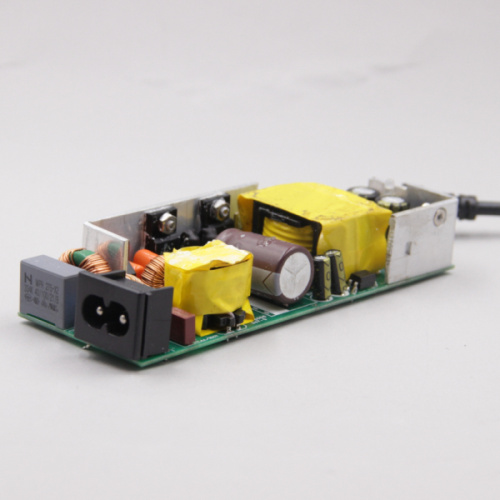

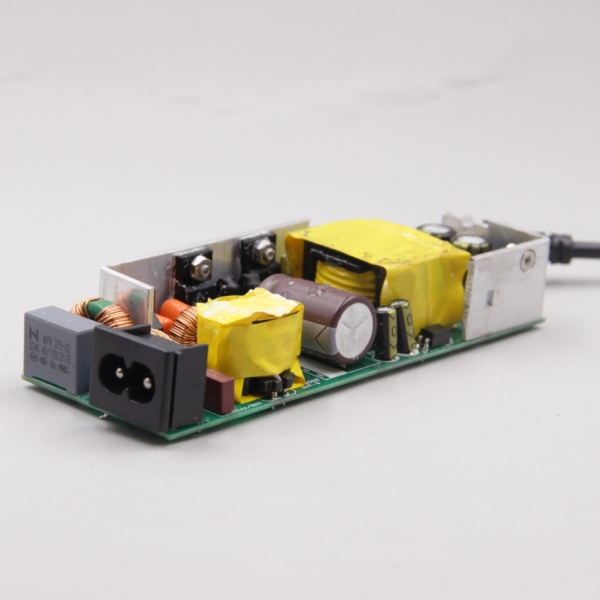

If Electronic Components looks good, you need to power up the PCB. Use a multimeter to measure the voltage of the power rail. Both the input and output of the regulator need to display the expected value.

Remove the overheated components and confirm that the voltage has returned to the desired value. If the observed voltage is still different from the expected voltage, more components may be damaged under the voltage line. Please refer to the schematic and remove the next component near the edge of the PCB.

If there is no sign that the component is overheating, look for a broken wire. Broken traces may cause voltage to be detected at some points of the trace, but not detectable at other points. Use a multimeter to narrow the discontinuities.

Check input/output ports

Cable Connectors I/O Connectors are also common points of failure. Damage to the Cable Connectors I/O Connectors port rarely shuts down the entire circuit, but usually causes system abnormalities. For example, an alarm controller will always sense that the door is open even when the door is closed, or the motor will continue to start.

If the I/O is protected by a fuse, Zener diode or varistor, please make sure they are working properly. If so, the logic IC or microcontroller may be damaged. The only way to find the problem is to replace the parts with quality parts.

Check the communication port

PCBs with communication ports (such as Ethernet and RS485) increase the risk of failure. When a communication failure is detected, please check for burned or broken communication ICs or Zener diodes and other protective components.

Optimize PCBA for troubleshooting

Use visual indicators to facilitate testing.

Circuit board testing is a tedious process, especially for problems such as short circuits. However, there are some ways to optimize the PCB for future troubleshooting. First, you can create test boards for voltage and key signals such as communications. This will prevent you from trying to short-circuit nearby traces by mistake with a multimeter probe.

It also helps to add LEDs as visual indicators for power, I/O, and communications. They can help you zoom in on problem areas with minimal detection.

If you can find hidden dangers on the PCB before custom pcb fabrication, you will be able to omit the above tedious inspection process. The correct DFM analysis software can easily detect the hidden dangers of PCB design files, allowing you to solve all the problems before PCB manufacturing Create hidden dangers.

Related Keywords