High Tech Electronic PCB

-

$7.00≥2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | infinite |

|---|---|

| Payment Type: | T/T,Paypal,Others |

| Incoterm: | FOB,CIF,EXW,FCA |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | shenzhen |

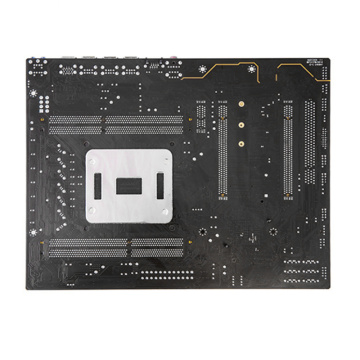

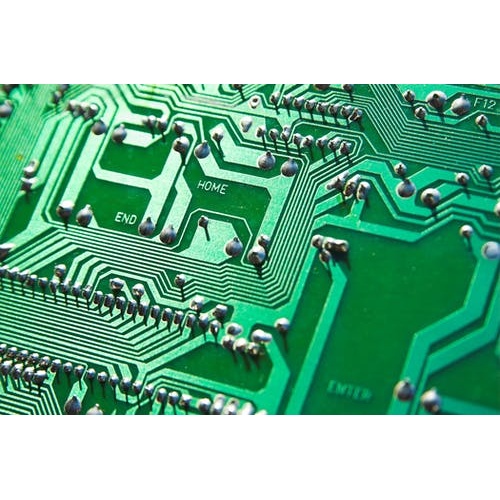

What's the process of Multi-layer circuit board PCB?

Multilayer pcb circuit board is a kind of printed circuit board which is laminated and bonded by alternating conductive pattern layers and insulating materials. The number of layers of the conductive pattern is more than three, and the electrical interconnection between the layers is realized through metallized holes. If one double-sided board is used as the inner layer, two single-sided boards are used as the outer layer, or two double-sided boards are used as the inner layer and two single-sided boards are used as the outer layer, the positioning system and the insulating bonding material are laminated together, and the conductive pattern is pressed together. The design requires interconnection, which becomes a four-layer or six-layer printed circuit board, also called a multilayer pcb circuit board.

Compared with the production process of general multi-layer boards and double-sided boards, the main difference is that the multi-layer boards have added several unique process steps: inner layer imaging and blackening, lamination, etchback and de-drilling. In most of the same processes, certain process parameters, equipment accuracy and complexity are also different. For example, the inner metallization connection of the multi-layer board is the decisive factor for the reliability of the multi-layer board, and the quality requirements for the hole wall are stricter than that of the double-layer board, so the requirements for drilling are higher. In addition, the number of stacks for each drilling of the multi-layer board, the speed and feed rate of the drill bit during drilling are different from those of the double-sided board. The inspection of finished and semi-finished multi-layer boards is also much stricter and more complicated than double-sided boards. Due to the complex structure of the multi-layer board, a glycerin hot-melt process with uniform temperature should be used instead of an infrared hot-melt process that may cause excessive local temperature rise.

Related Keywords