Laser Engraver for Creating PCB

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowHow do you make PCBs at home?

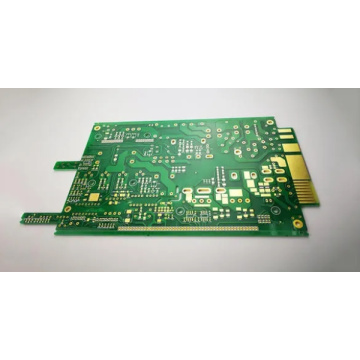

As an electronic hobby author, you often need custom pcb fabrication. Especially during the experiment, if they are all sent to the factory for Quick-turn PCB fabrication, it is not economical in terms of custom circuit board cost manufacturing and time. Today I will show you how to make cheap pcb manufacturing at home.

The first step is of course the circuit design. The design software I use is Altium Ddesigner 18. This software is very convenient for personal production of small projects. The design process is

1. Make a schematic diagram of the circuit;

2. Choose the correct package for each original;

3. Convert the schematic diagram into a PCB, and adjust the original on the PCB according to the circuit requirements.

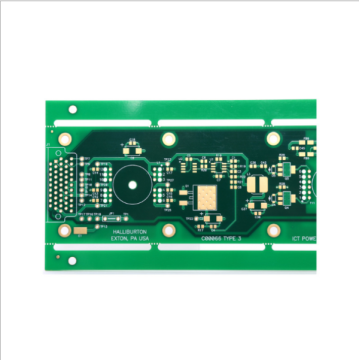

After completing the PCB production, the PCB wiring diagram needs to be printed out. The picture is the wiring diagram printed on the thermal transfer paper using a laser printer. After the PCB is made, the PCB wiring diagram needs to be printed out.

Then use a thermal transfer machine (you can use an electric iron, that is, the success rate is relatively lower) to transfer to the copper clad laminate. I usually set the temperature to 175 degrees Celsius and go through the transfer machine 3 times.

The copper clad laminate must be cleaned before transfer, and it can be processed with sandpaper above 400. The quality of the transfer today is very good, without any missing lines. If there are missing lines, you can use an "oily marker" to repair it.

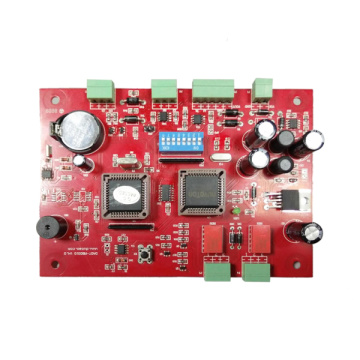

The next step is to corrode the copper clad laminate. I usually use ferric chloride for corrosion. Ferric chloride is relatively easy to obtain and can be sold in chemical reagent stores in any city. Usually the ratio is "ferric chloride: water" in a ratio of 1:2 (by weight).

Fast PCB Manufacture Low Cost The corrosion rate is still very fast. Generally, it takes about 5 minutes to get it. The only downside of using ferric chloride is that you have to take out the circuit board solution to observe the corrosion. The corroded board should be cleaned and turned. Use turpentine oil and thinner (a solvent for paint) to clean the printed lines and use the holes. The printed lines on the circuit board can be cleaned off. This is also very easy to buy at any paint shop, and the price is very cheap. .

Related Keywords