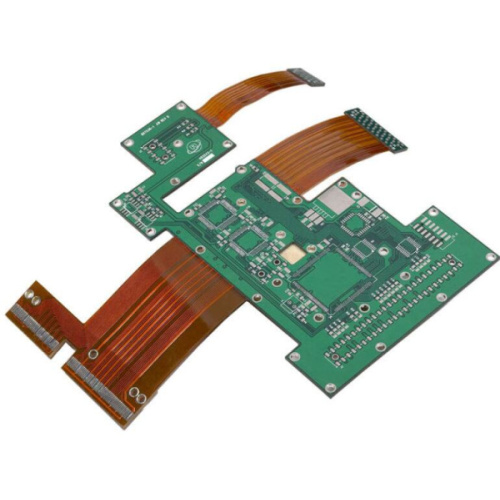

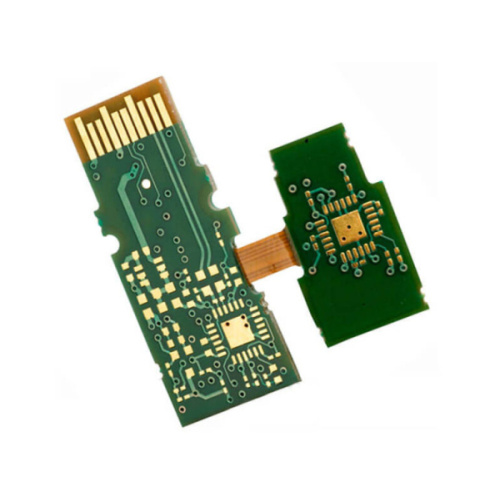

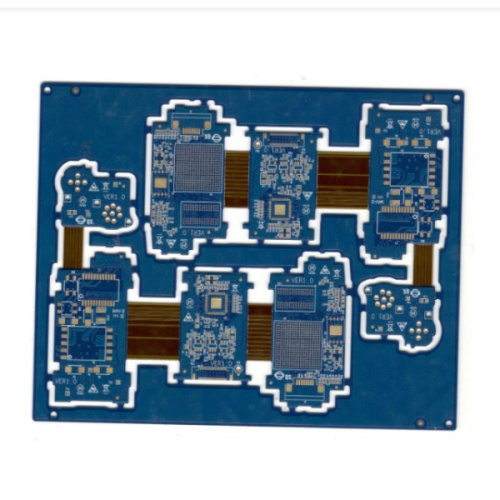

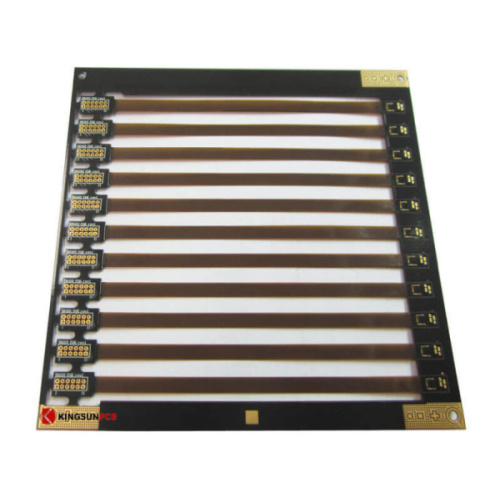

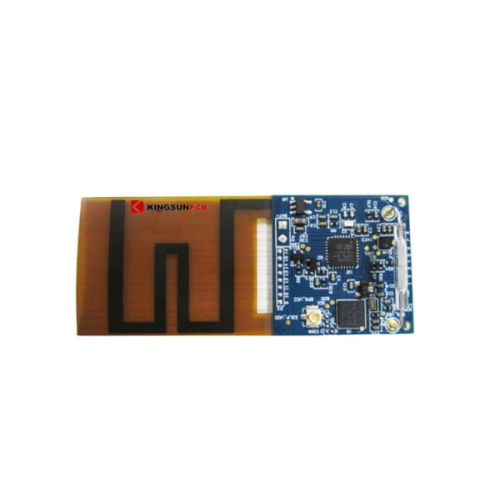

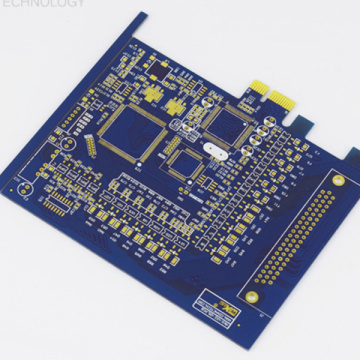

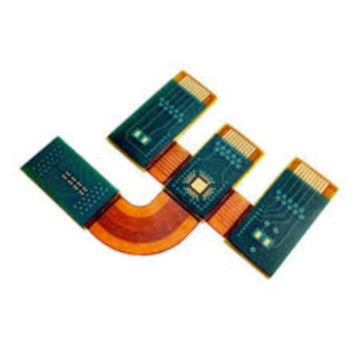

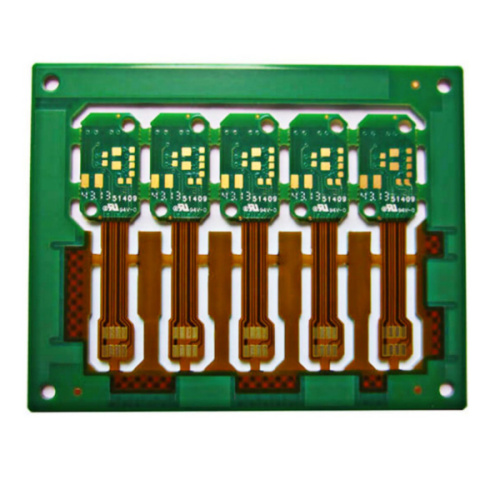

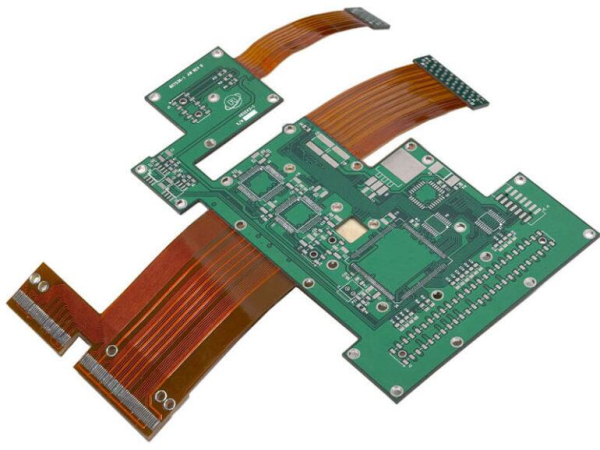

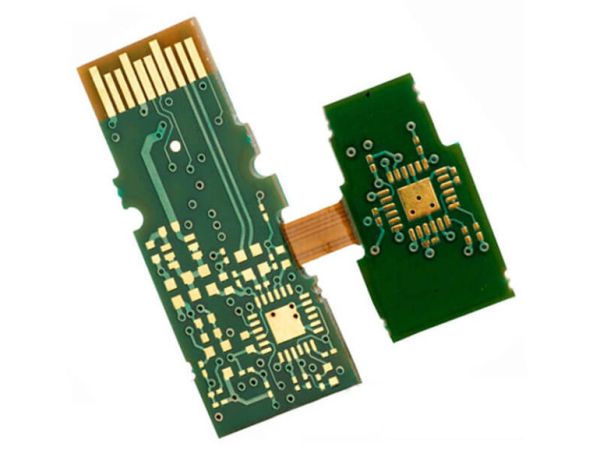

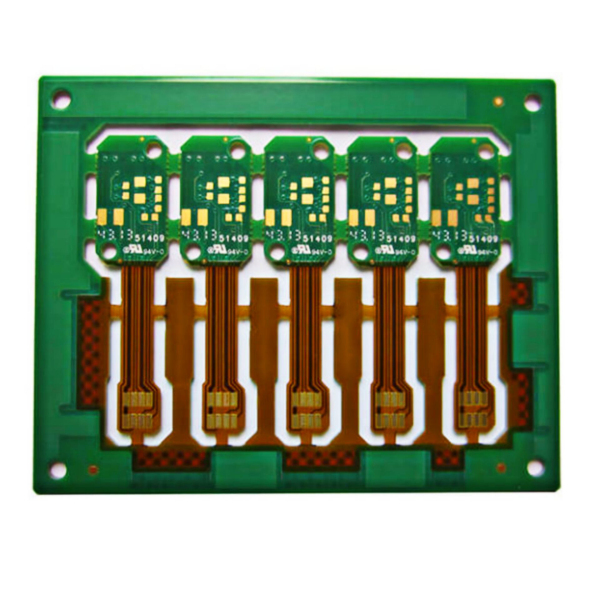

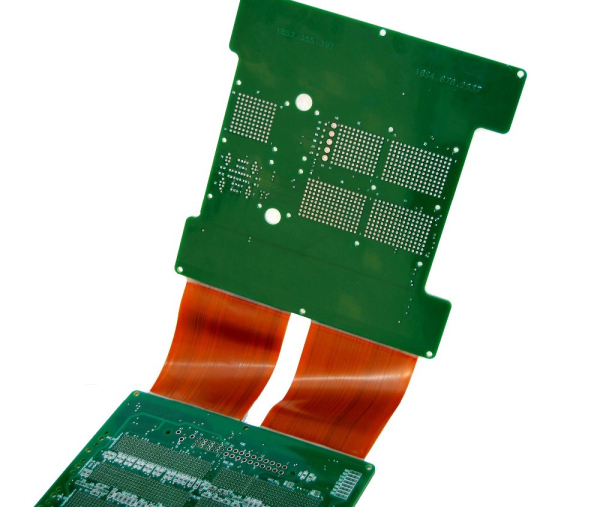

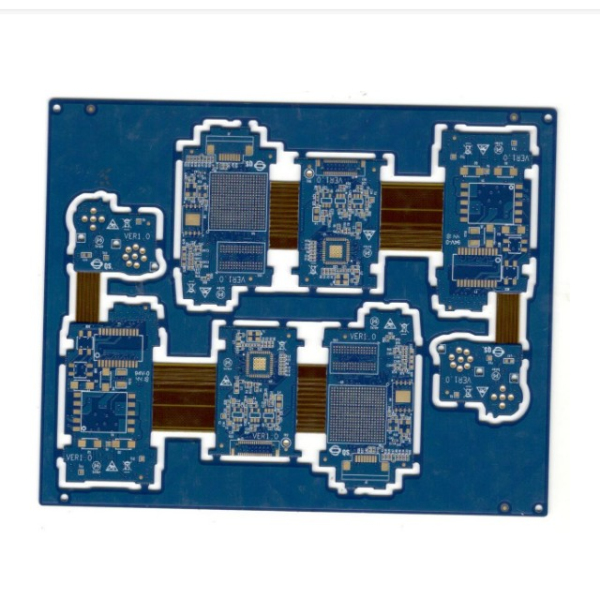

6 layer Rigid-flex Immersion Gold PCB

-

$32.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is immersion gold plating?

As the integration level of origin electronics IC becomes higher and higher, IC pins become more denser. The vertical spray tin process is difficult to flatten the thin pads, which brings difficulty to Surface-Mount (SMT) & BGA Assembly; in addition, the shelf life of the spray tin plate is very short. The gold-plated board just solves these problems: 1. For the surface mount process, especially for 0603 and 0402 ultra-small surface mounts, because the flatness of the pad is directly related to the quality of the solder paste printing process, and the quality of the subsequent reflow soldering Play a decisive influence, therefore, the whole board gold plating is common in high-density and ultra-small surface mount processes. 2. In the trial production stage, the influence of the purchase of Electronic Components and other factors is often not that the PCB is soldered immediately, but often it takes several weeks or even months to use it. The shelf life of the gold-plated board is more than The lead-tin alloy is many times longer, so everyone is willing to use it. Besides, the cost of the gold-plated PCB in the sample stage is almost the same as that of the lead-tin alloy board. But as the wiring becomes denser, the line width and spacing have reached 3-4MIL. Therefore, the problem of gold wire short circuit is brought about: As the frequency of the signal becomes higher and higher, the signal transmission in the multi-plated layer caused by the skin effect has more obvious influence on the signal quality. The skin effect refers to: high frequency alternating current, the current will tend to concentrate on the surface of the wire to flow. According to calculations, the skin depth is related to frequency.

In order to solve the above problems of gold-plated boards, PCBs using gold-plated boards mainly have the following characteristics:

1. Because the crystal structure formed by immersion gold and gold plating is different, immersion gold will be golden yellower than gold plating, and customers will be more satisfied.

2. Because the crystal structure formed by immersion gold and gold plating is different, immersion gold is easier to weld than gold plating, and will not cause poor welding and cause customer complaints.

3. Because the immersion gold board only has nickel and gold on the pad, the signal transmission in the skin effect will not affect the signal on the copper layer.

4. Because immersion gold has a denser crystal structure than gold plating, it is not easy to produce oxidation.

5. Because the immersion gold PCB only has nickel and gold on the pads, it will not produce gold wires and cause slight shortness.

6. Because the immersion gold board only has nickel and gold on the pads, the solder mask on the circuit and the copper layer are more firmly bonded.

7. The project will not affect the distance when making compensation.

8. Because the crystal structure formed by immersion gold and gold plating is different, the stress of the immersion gold plate is easier to control, and for products with bonding, it is more conducive to bonding processing. At the same time, it is precisely because the immersion gold is softer than the gilding, so the immersion gold plate is not wear-resistant as the gold finger.

9. The flatness and stand-by life of the immersion gold board are as good as the gold-plated board.

Therefore, most factories currently use the immersion gold process to produce gold plates. However, the immersion gold process is more expensive (higher gold content) than the gold plating process, so there are still a lot of cheap pcb manufacturing using gold plating processes (such as remote control boards, toy boards).

Related Keywords