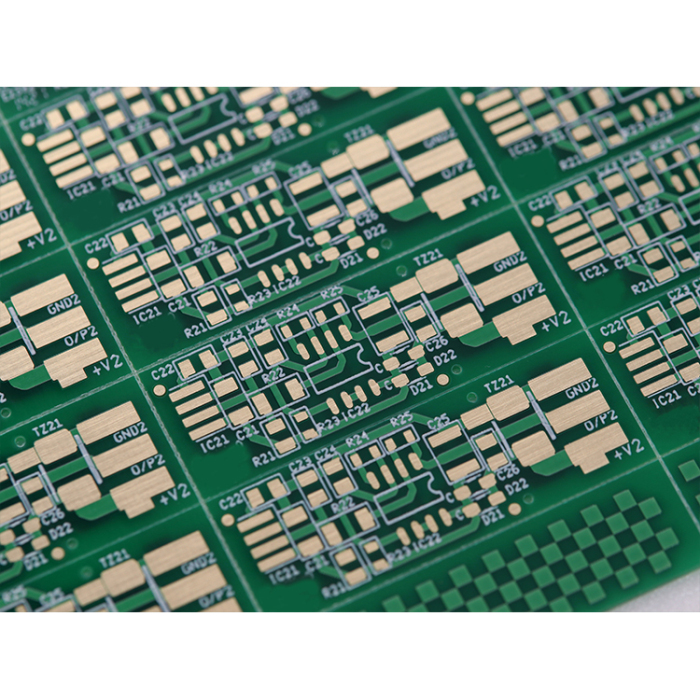

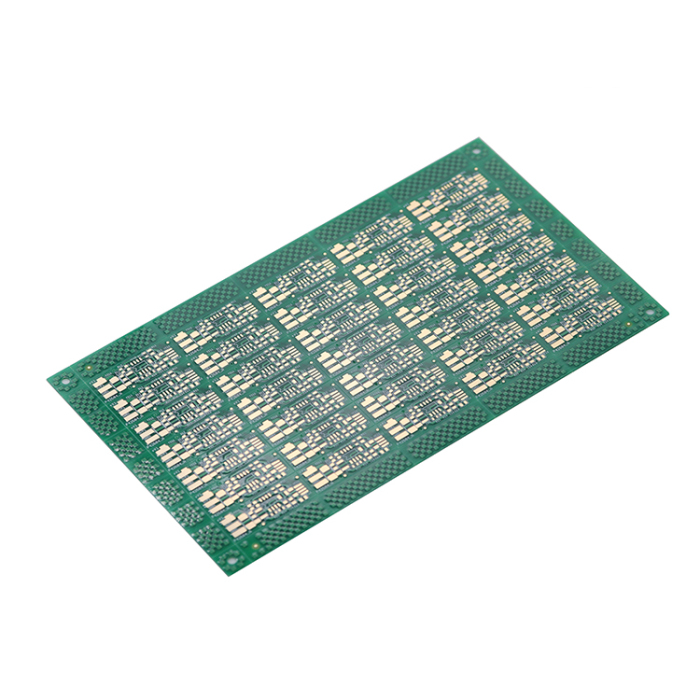

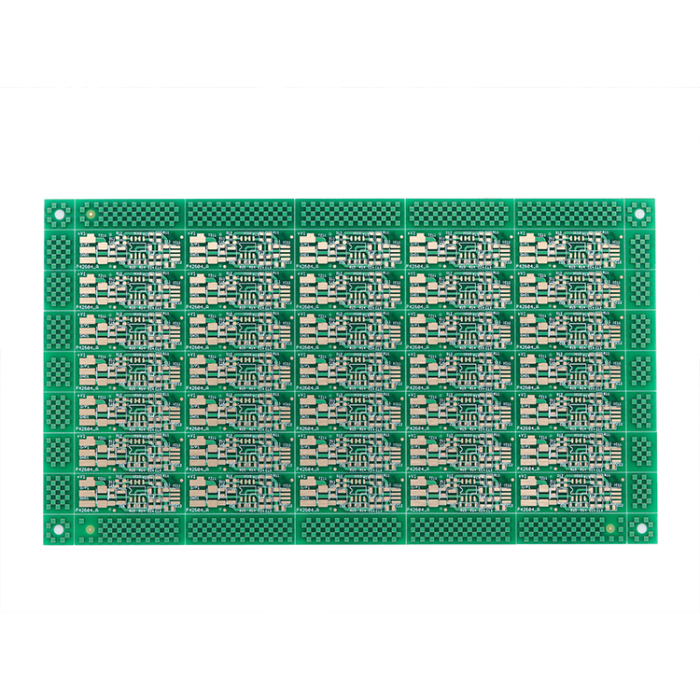

ceramic substrate printed board

-

$0.82≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Land, Air, Express, Ocean

- Port:

- shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000pcs/day |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,EXW |

| Transportation: | Land,Air,Express,Ocean |

| Port: | shenzhen |

How are ceramic PCB made?

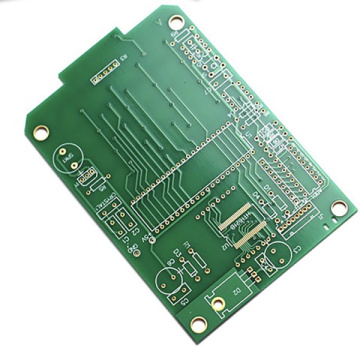

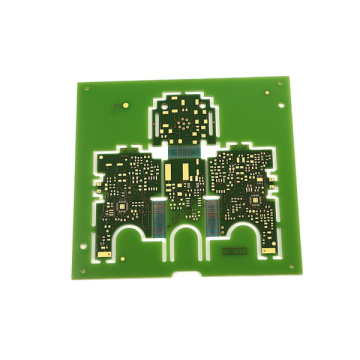

Ceramic PCB

It is a kind of thermally conductive organic ceramic substrate printed board with a thermal conductivity of 9-20W/m.k prepared at a temperature below 250°C using thermally conductive ceramic powder and organic adhesives.

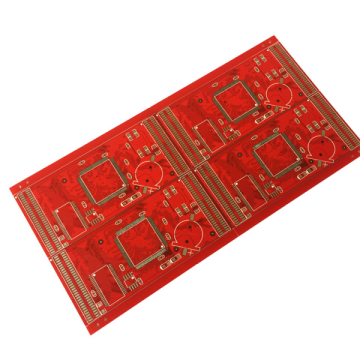

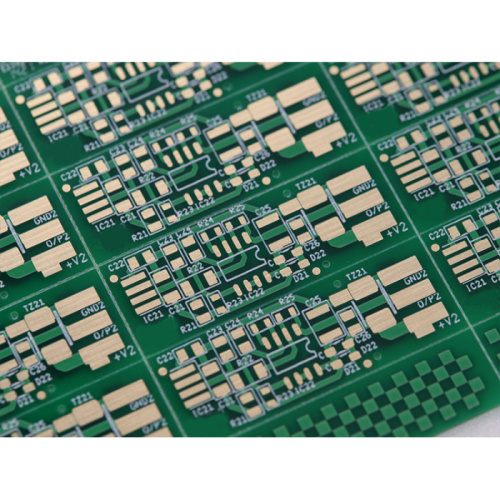

With the gradual deepening of electronic technology in various application fields, the highly integrated PCB has become an inevitable trend. The highly integrated package module requires a good heat dissipation carrying system, while the traditional PCBR FR-4 and CEM-3 are in TC (thermal conductivity) The disadvantages of electronic technology have become a bottleneck restricting the development of electronic technology. In recent years, the rapid development of the LED industry has also put forward higher requirements for the TC index of its carrying PCB. In the field of high-power LED lighting, materials with good heat dissipation properties such as metals and ceramics are often used to prepare PCBs. At present, the thermal conductivity of high thermal conductivity Quick-turn Aluminum PCB fabrication is generally 1-4W/M. K, while the thermal conductivity of Ceramic PCB According to its preparation method and material formula, it can reach about 220W/M.K.

Related Keywords