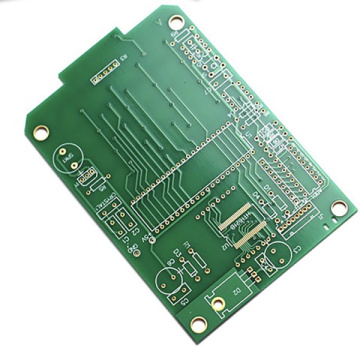

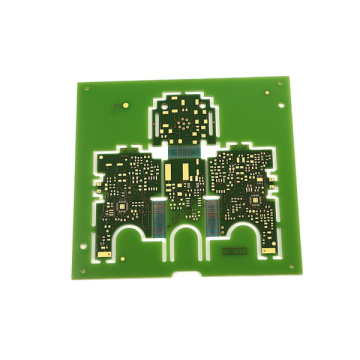

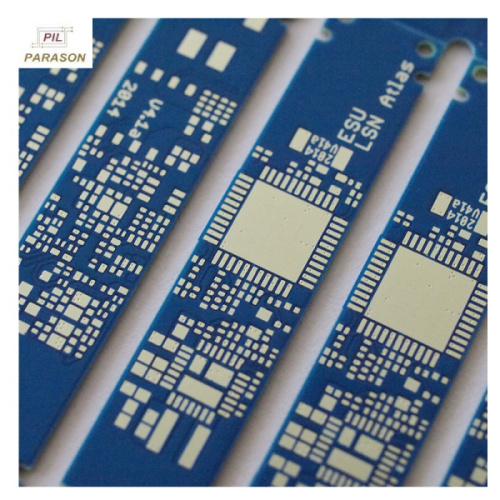

Resistant Flame Temperature Resistant Flame Retardant pcb

-

$10.82≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal,Others |

|---|---|

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,Express,Others |

Is PCB heat resistant?

PCBA Manufacturing Although lead-free soldering can be performed in the traditional temperature range (the so-called drop-in process), it is not easy for most Wave Solder for PCBA to do this. In particular, if each product can be successfully welded at the traditional peak value of 235°C, a very good DFM, equipment and process coordination is required. The mastery of these SMT processing skills is not easy. So for many users, lead-free means higher soldering temperature. In the case of higher temperature, can the original PCB material still withstand the heat without reliability problems?

In the traditional PCBA processing technology, the softening temperature (Tg, Glass Transition Temperature) of the PCB has always been a major concern.

However, in the research of lead-free generally high temperature, the industry discovered that there is another characteristic on PCB substrate that is more important for our application.

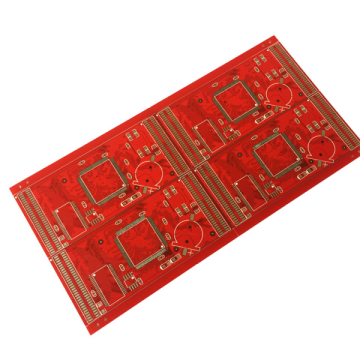

Another feature is the discoloration that affects the appearance. Some FR4 material Low Cost Prototype PCB will change color when the temperature is above 240℃ (cheap custom pcb fabrication becomes deeper and darker brown). The lead-free soldering temperature may be as high as 245 to 250°C, which will cause appearance problems for the product. Although the quality of the substrate (such as insulation, etc.) has not changed at this time, it is always a worrying factor for users.

As there is currently no material with a Tg exceeding 260°C, the traditional problem of warping during welding still exists. Surface-Mount (SMT) & BGA Assembly is even more serious with the increase of welding heat. In this regard, there has always been a lack of test indicators, so users have to deal with them by themselves.

Related Keywords