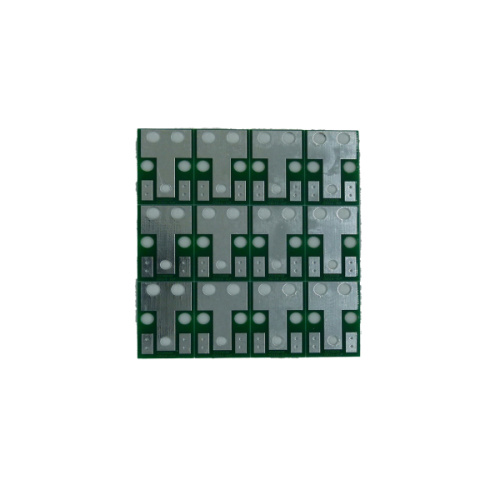

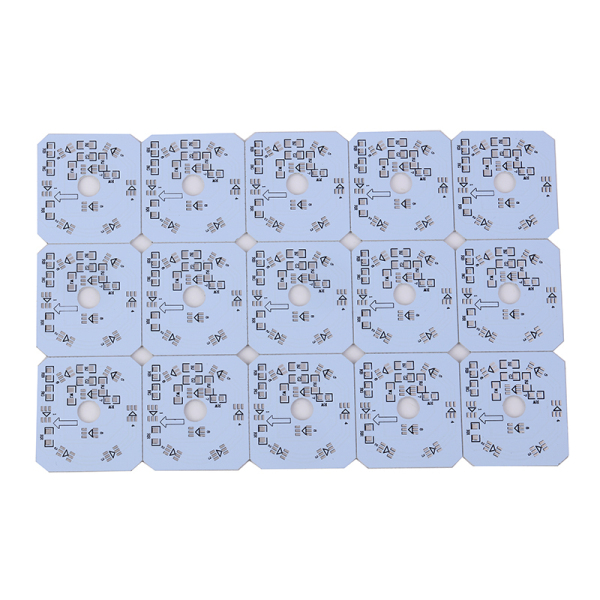

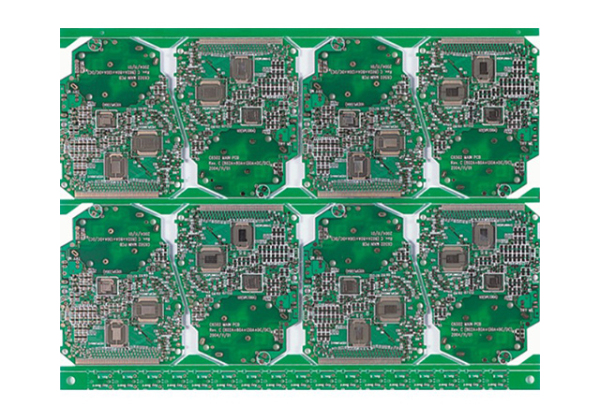

Trade Assurance mcpcb pcb clad laminate aluminum

-

$0.80≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

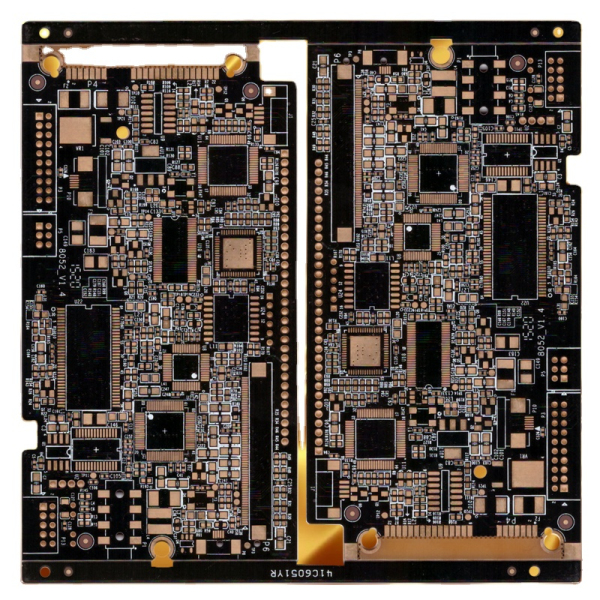

Which laminate is used for making flexible PCBs?

The most important material in Rigid-Flex Board is its base substrate material. It is the material on which the entire PCB stands. In rigid PCB, the substrate material is usually FR-4. However, in Custom Flexible PCB fabrication, the commonly used substrate materials are polyimide (PI) film and PET (polyester) film. In addition, polymer films, such as PEN (polyphthalate) can also be used. Ethylene formate), PTFE and aramid etc.

Polyimide (PI) "thermosetting resin" is still the most commonly used material for Flex PCB. It has excellent tensile strength, is very stable in a wide operating temperature range of -200 O C to 300 O C, has chemical resistance, excellent electrical properties, high durability and excellent heat resistance. Unlike other thermosetting resins, it can maintain its elasticity even after thermal polymerization. However, the disadvantages of PI resin are poor tear strength and high moisture absorption rate. On the other hand, PET (polyester) resin has poor heat resistance, "making it unsuitable for direct welding", but it has good electrical and mechanical properties. Another substrate, PEN, has a better mid-level performance than PET, but not better than PI.

Related Keywords

Related Keywords