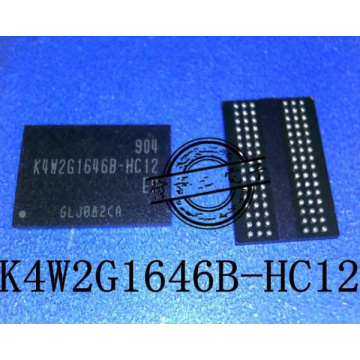

100% new original electronics IC

-

$1.60≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is IC advantages and disadvantages?

The entire physical size of Electronic Components of IC is extremely small than that of discrete metal base printed board circuit. The weight of an IC is very less as compared entire discrete circuits. It's more reliable. Because of their smaller size it has lower power consumption. It can easily replace but it can hardly repair, in case of failure.

After the packaging process of integrated circuit (IC) chips, they must undergo rigorous testing to ensure the quality of the Electronic product. The appearance of the chip is an indispensable and important link, which directly affects the quality of IC products and the smoothness of subsequent production links. Proceed. There are three methods of appearance inspection: one is the traditional manual inspection method, which mainly relies on visual inspection and manual sub-inspection. The reliability is low, the inspection efficiency is low, the labor intensity is large, and the inspection defects have omissions, which cannot be adapted to PCB and PCBA mass production; 2. It is a detection method based on laser measurement technology. This method requires high equipment hardware, correspondingly high cost, high equipment failure rate, and more difficult maintenance; the third is a detection method based on Turkey PCB Assembly machine vision, which is easy to detect due to the easy hardware of the detection system. Integration and implementation, fast detection speed, high detection accuracy, and relatively easy maintenance. Therefore, the application in the field of chip appearance inspection is becoming more and more common, which is a development trend of IC chip appearance inspection,also will be big influence for the PCBA Manufacturing and Microwave radio frequency board production .

Related Keywords