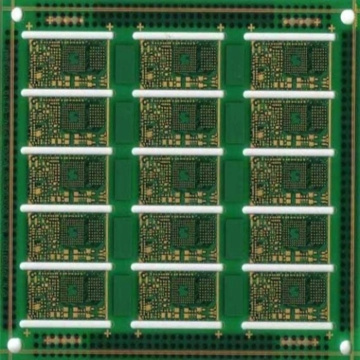

High Temperature and Quality PCB Assembly

-

$0.50≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

Your message must be between 20 to 2000 characters

Contact NowWhat is BGA assembly?

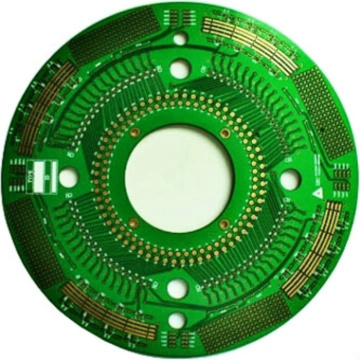

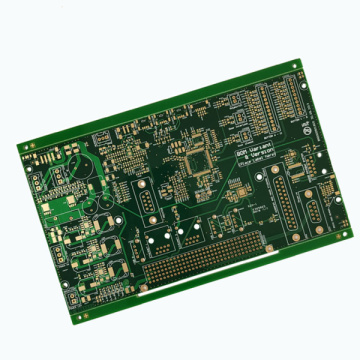

BGA package memory: The I/O terminals of the PCBA BGA package are distributed under the package in the form of circular or columnar solder joints in an array. The advantage of BGA technology is that although the number of I/O pins has increased, the pin spacing has not been reduced. Increased, thereby improving the PCB assembly yield; although its power consumption increases, but BGA can be welded with a controlled collapse chip method, which can improve its electrical and thermal performance; thickness and weight are reduced compared with the previous packaging technology; parasitic The parameters are reduced, the signal transmission delay is small, and the frequency of use is greatly improved; the Surface-Mount (SMT) &BGA assembly can be coplanar welding, and the reliability is high.

TinyBGA packaged memory: Memory products using TinyBGA package technology are only 1/3 of the TSOP package with the same capacity. The pins of TSOP packaged memory are led out from around the chip, while TinyBGA is led out from the center of the Electronic Components chip. This method effectively shortens the signal transmission distance, and the length of the signal transmission line is only 1/4 of the traditional TSOP technology, so the signal attenuation is also reduced. This not only greatly improves the anti-interference and anti-noise performance of the originality electronics IC , but also improves the electrical performance of the Flame resistant PCB.

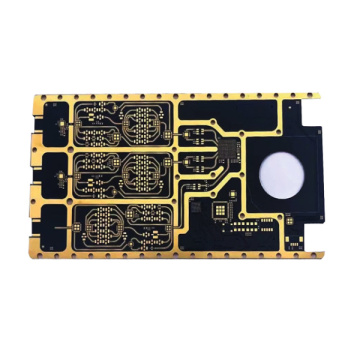

The substrate or intermediate layer is a very important part of the BGA package. In addition to interconnect wiring, it can also be used for impedance control and for the integration of inductance/Electronic Resistor and Capacitor. Therefore, the substrate material is required to have a high glass transition temperature rS (about 175~230°C), high dimensional stability and low moisture absorption, as well as good electrical properties and high reliability. The metal film, the insulating layer and the substrate medium should also have higher adhesion properties.

Related Keywords